What is a ductless fume hood?

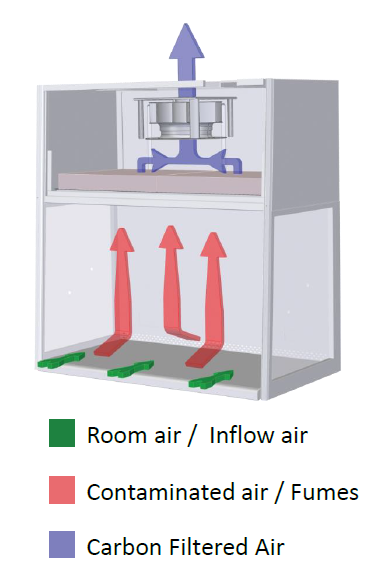

A ductless fume hood, also called a filtering chemical fume hood, is a laboratory workstation that provides protection of the user against chemical hazards. Just like a ducted fume hood, it creates an up-flow of air. But instead of sending the air outside via the HVAC system, a ductless fume hood has a ventilator that pulls the air through carbon filters. The carbon filters contain active charcoal that has chemical coatings. The chemical coatings can capture chemical vapours through a process called adsorption (molecular attraction). For different types of chemicals (solvents, acids, bases, ammonia, formaldehyde, …) there are different types of coatings.

Analis is a distributor of Erlab.

Erlab has invented this technology and is the current market leader in ductless fume hoods.

- The environment: with ductless fume hoods, you capture the chemicals and process them with chemical waste instead of sending them outside.

- Energy efficiency: laboratory air is conditioned. In the winter you heat the air and in the summer, you cool the air. This takes a lot of energy. A classical ducted fume hood sends the heated or cooled air outside with a high flow rate. This is an enormous energy loss of thousands of euros per year. A ductless fume hood only has the electrical usage of the FAN and electronics, which is around 100 euro a year.

- Installation: the installation of a ductless fume hood is limited to the assembly and validation. A ducted fume hood on the other hand also needs to be connected to a HVAC system.

- Flexibility: with ducted fume hoods, you need to consider the maximum capacity of the HVAC system. Sooner or later you reach a max number of fume hoods, and then you need to expand your entire HVAC system to connect more units. Using ductless fume hoods, you don’t have any limitations in terms of number of units. Also, if you want to move to another lab, ductless fume hoods are much easier to move, because they don’t need to be detached and re-attached to the HVAC system. You simply move the cabinet and re-validate it.

- Use of powder chemicals: powders chemicals and classical ducted fume hoods are not a good combination. If powders are removed via the HVAC system, they can accumulate in corners of the HVAC systems. This is because powder particles are heavier than air, so when making a turn, they move to the corners. Ductless fume hoods on the other hand, can be easily configured with HEPA filters below the carbon filters. This way, you capture the powder particles. Sometimes only powder chemicals are used, and no carbon filter is needed. ‘In that case, it can also be called a powder weighing station or balance enclosure when the cabinet is fitted with a Trespa work surface or a marble table.

- Weighing: a classical ducted fume hood is connected to the outside via the HVAC system. Outside air has a very variable speed. This speed variation will partially translate in a variable speed and pressure of the air in the ducted fume hood. Pressure variations have an influence on weighing results. A ductless fume hood is not connected to the outside, so therefore has a much more stable flow. This makes it more suitable for weighing applications. For more info: read the application note weighing in a ductless fume hood.

- Carbon filters have a limited speed to capture chemical vapours. When the evaporation is very high, they cannot be used. Only around 70% of all applications can be done in ducted fume hoods. The risk assessment can determine if a ductless fume hood is suitable for a certain application or not.

- The risk assessment for a ductless fume hood is much more detailed. The risk assessment is the basis to see if the technology is suitable, what sensors are needed, what filters are needed and what the lifetime of the filters will be. The supplier can offer support for filling in this risk assessment.

- The filters need to be changed on a routine base. Carbon filters get saturated after a certain period or reach their max lifetime. When this happens, they need to be replaced. This is a returning cost. In practice, the cost of the filter is in most cases a lot lower than the cost of the energy loss when using a ducted fume hood. The cost of the filter can be estimated in advance by the manufacturer based on the risk assessment.

A ductless fume hood is at the very least as safe as a ducted fume hood if you do the risk assessment properly. During the risk assessment, the manufacturer evaluates if the chemical vapours can be captured and they include a certain safety margin. In case the user underestimates the used chemicals, the filters will be saturated earlier than predicted and the bottom filters are not replaced in time. In that case there is a sensor that will give the user a signal that the first filter layer is saturated, and there is still a backup filter that gives the user more than enough time to replace the saturated filter layer. When you change your application, it is important to contact the distributor to adjust the risk assessment. They can re-confirm or adjust the configuration and re-calculate the new filter lifetime.

Also, there is NFX 15211-2009 standard that defines a set of tests to insure that the cabinet is working properly. These tests are performed during installation and yearly maintenance.

The manufacturer needs all information to evaluate what chemicals are evaporating, and at what speed.

- The application: how the chemicals are used is important to estimate the evaporation surface and speed. Also the temperature of the application can have an influence on the evaporation.

- The used chemicals: the name of the chemicals (or CAS number) is needed to evaluate what coatings are needed on the active charcoal.

- The concentration of the chemicals

- The duration of each experiment/manipulation

- The frequency of each experiment/manipulation.

Complete your risk assessment here

Maximize Energy Efficiency and Reduce Costs

A study (*) by the Center for Energy Efficient Laboratories highlights that ducted fume hoods are the largest energy users in the lab.

The report, which examines lab equipment energy use in California.

(*) For more detailed insights, refer to the Market Assessment of Energy Efficiency Opportunities in Laboratories (2015) by My Green Lab, (market assessment available here).

Download the study report

Having identified ducted fume hoods as the most energy-consuming type of equipment, and therefore those on which the impact of a reduction will potentially be the strongest, we can very logically imagine the considerable impact of energy savings nationwide by transitioning to ductless systems.

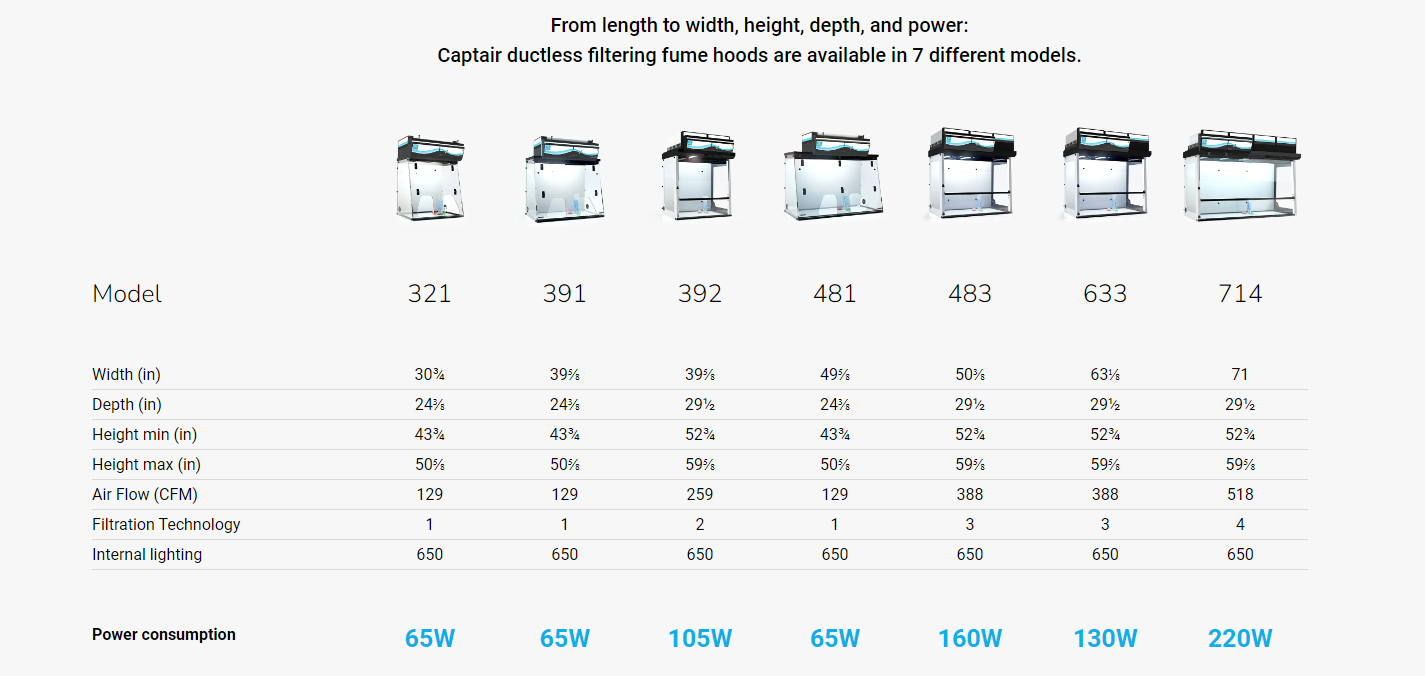

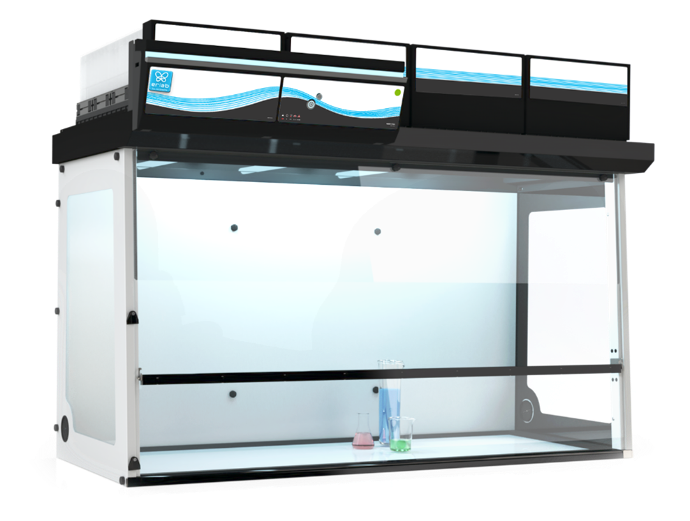

Captair ductless filtering fume hoods product overview