Qu'est-ce qu'un système d'eau de laboratoire ?

Pour la plupart des applications dans un environnement de laboratoire, la qualité de l'eau domestique n'est pas suffisante. Pensez à la présence de concentrations élevées d'ions, de matières organiques, de particules (colloïdes) et de micro-organismes. Tous ces contaminants peuvent influencer les résultats de vos analyses en laboratoire. Un système d'eau de laboratoire est un système qui purifie l'eau jusqu'à la qualité souhaitée pour votre application en combinant différentes techniques de purification.

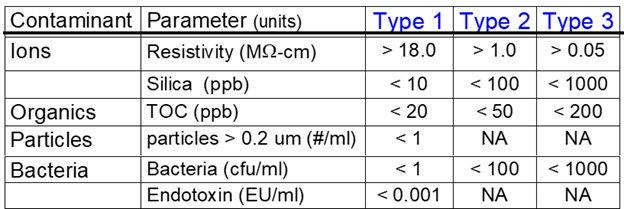

Pour les applications en laboratoire 3 types d'eau sont définis en fonction de leur pureté : type I, type II et type III.

Qu'est-ce que l'eau de type III ?

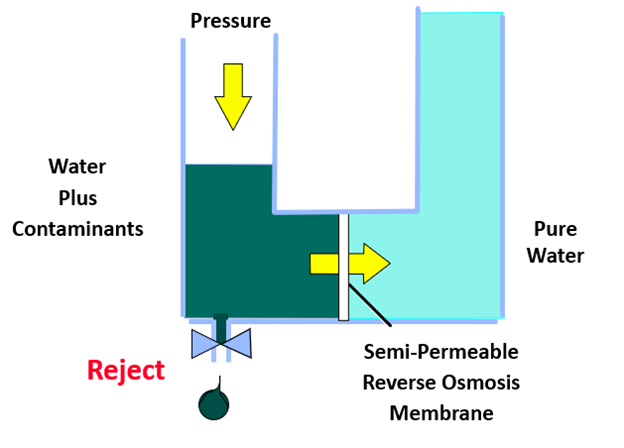

L'eau de type 3 est également appelée eau d'osmose inverse (OI) ou eau de qualité laboratoire. Elle est produite à partir de l'eau du robinet en appliquant deux techniques de purification importantes : la préfiltration et l'osmose inverse. Lors de la préfiltration, les filtres à particules capturent toutes les particules dont la dimension est supérieure à celle des pores. Parfois, des filtres à charbon actif sont également utilisés dans la préfiltration. Ces filtres retiennent principalement les matières organiques de l'eau par un processus appelé adsorption. Le composant le plus important des systèmes d'OI est bien sûr la membrane d'osmose inverse (OI). Dans ce composant, l'eau est pompée à travers une membrane semi-perméable contre la pression osmotique. Cette étape permet d'éliminer une grande partie des contaminants présents dans les eaux usées : ions, bactéries, colloïdes, matières organiques, pyrogènes...

Les applications typiques pour l'eau de type III sont le rinçage manuel de la verrerie, le rinçage final des lave-vaisselle de laboratoire, le remplissage des bains-marie, des chambres climatiques, des autoclaves,...

Qu'est-ce que l'eau de type II ?

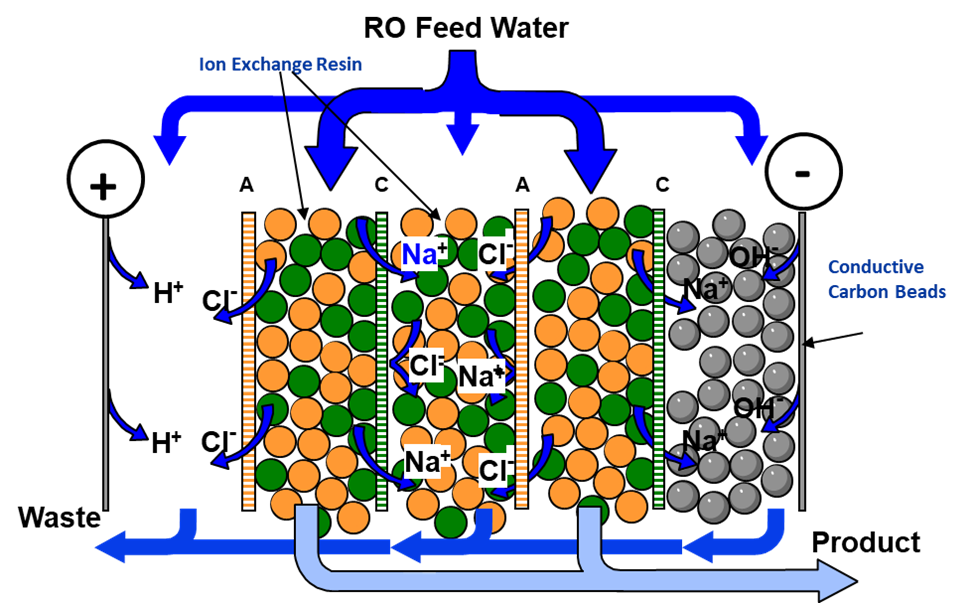

L'eau de type II est également appelée eau EDI, eau pure ou eau de qualité analytique. Les premières étapes sont dans la plupart des cas les mêmes que pour l'eau de type III. Cela signifie que les instruments combinés qui produisent à la fois de l'eau de type III et de type II à partir d'eau de table sont faciles à produire. Pour purifier l'eau de type III jusqu'à la qualité de l'eau de type II, on applique dans la plupart des cas deux étapes de purification supplémentaires : l'électrodéionisation et l'irradiation UV. Le module d'électrodéionisation (EDI) est constitué d'une colonne de résine avec une électrode positive, une électrode négative et plusieurs membranes semi-perméables. Il élimine une très grande partie de la concentration d'ions déjà réduite. La lampe UV irradie ensuite l'eau avec une lumière d'une longueur d'onde de 254 nm. La lumière UV de cette longueur d'onde est très efficace contre l'ADN. La lumière UV tue donc tous les micro-organismes et rend l'eau stérile.

Les applications typiques pour l'eau de type II sont : les tampons, les solutions de pH, les milieux de culture, les analyseurs cliniques...

Qu'est-ce que l'eau de type I ?

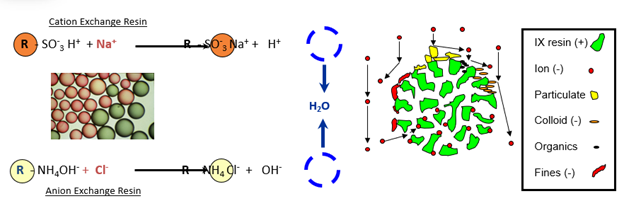

L'eau de type I est également appelée eau ultrapure ou eau de qualité réactif. Elle peut être produite en ajoutant quelques techniques de filtration supplémentaires aux techniques utilisées pour l'eau de type II, ou elle peut également être produite directement à partir de l'eau de type III. Dans la pratique, pour la plupart des applications, l'eau de type I est produite directement à partir de l'eau de type III/l'eau RO. Pour produire de l'eau de type I à partir d'eau de type II ou III, trois étapes de purification supplémentaires sont nécessaires : une double lampe UV, une colonne d'échange d'ions et un filtre à charbon. La lampe UV irradie la lumière UV à deux longueurs d'onde : 254 nm et 185 nm. La lumière UV de longueur d'onde 254m tue tous les micro-organismes et la lumière UV de 185 nm oxyde les matières organiques sans les éliminer. Dans la colonne d'échange d'ions, la concentration d'ions est encore réduite. Cette colonne est constituée de résine échangeuse d'anions et de résine échangeuse de cations. Dans la dernière étape, la matière organique oxydée est éliminée par le filtre à charbon actif.

Les applications typiques pour l'eau de type I sont : HPLC, GC, AA, ICP-MS, solutions tampons, milieux de culture pour la culture de cellules humaines et animales, réactifs pour la biologie moléculaire...

Quelles sont les solutions proposées par Analis ?

Analis est distributeur des systèmes de purification d'eau Rephile en Belgique et aux Pays-Bas.

Demandez à nos experts

La meilleure solution pour le coût total de possession

La meilleure solution pour la flexibilité et le confort de l'utilisateur

Grandes unités de production

(jusqu'à 500l/h)

Guide de sélection : Spécifications & applications des différents systèmes de purification d'eau

| Kit de système d'eau |

Application | Sources d'eau d'alimentation compatibles | Taux de production à 25°C |

| Genie U 32 | Eau ultra-pure (type I) et eau d'osmose inverse (type III) | Robinet / eau potable | 32l/h |

| Genie PURIST | Eau ultra-pure (type I) | Eau pré-traitée | - |

| Genie A | Eau ultra-pure (type I) | Robinet / eau potable | - |

| Genie E 15 | Eau pure (type II) | Robinet / eau potable | 15l/h |

| Genie R 32 | Eau d'osmose inverse (type III) | Robinet / eau potable | 32l/h |

| Genie G 15 with TOC set | Eau ultra-pure (type I) et pure (type II) | Robinet / eau potable | 15l/h |

| Large Genie E 60 | Eau pure (type II) | Robinet / eau potable | 60l/h |

| Large Genie R 80 | Eau d'osmose inverse (type III) | Robinet / eau potable | 80l/h |

| NuZar U 24 | Eau ultra-pure (type I) et eau d'osmose inverse (type III) | Robinet / eau potable | 24l/h |

| NuZar Q | Eau pure (type II) | Eau Pré-traitée | - |

| NuZar E 10 | Eau pure (type II) | Robinet / eau potable | 10l/h |

| NuZar R 24 | Eau d'osmose inverse (type III) | Robinet / eau potable | 24l/h |

| Super-Genie E 500 | Eau pure (type II) | Robinet / eau potable | 500l/h |

| Super-Genie RO 600 | Eau d'osmose inverse (type III) | Robinet / eau potable | 600l/h |

| Genie De-Ion Unit | Eau ultra pure de qualité ICP | Eau ultra-pure (type I) | - |

Nos produits

Genie U produces ultrapure water (Type I water) and RO water from tap water directly, it offers desired solutions for research professionals who work with varieties of applications utilizing Type I ultrapure and RO pure water in the lab. Quality of ultrapure water meet or exceeds ASTM, CLSI, CAP, and ISO Type I water standards.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via CAN cable or wireless. “1+N” Mode.

- Automatic temperature compensation allows RO production rate stable over a wide range of temperature.

- Fully automated control system has cleaning, rising, flush and many other functions.

- System automatically rinses a new RO membrane. Users do not need to set special rinse program for a new RO membrane.

- A bypath automatically sends the RO water to the drain if it does not meet a preset quality standard. The RO drain water is reused to increase the water yield thus it is more environmentally friendly.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- The Chlorine cleaning and pH cleaning functions keep the maintenance easier and ensure optimal water quality.

- Leak protector incorporated can prevent damage from a water leakage by shutting the feed water off in case of unexpected leaking.

- Tank recirculation model guarantees water quality in the tank.

Effective TOC level controlment

- Built-in 185/254 nm dual wavelength lamp reduces TOC level in ultrapure water.

- A tank Sanitization Module is equipped to effectively keep microbial growth at a lower level by LED UVC light.

- On-line TOC monitor based on complete oxidation methods (for TOC models).

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. Cartridge

- Pre-filtration pack removes most large particles, chlorine, calcium or organic compounds to protect RO membrane to extend their usable life..

- AC Pack contains special activated carbon to remove organic impurities and free chlorines.

- Ultra purification cartridge is filled with LeFilTM and OrganeFilTM media to remove trace ions and organics.

2. Control console

- 8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

- The control console can be placed on the bench or inside a drawer for further flexibility and space saving.

- The console screen and dispenser screens are water-drop proof. You can operate the console and dispenser with latex gloves on.

- The system has two level password protection on display menu for safety purposes.

3. Dispenser

- The volumetric function can automatically deliver the water volume you need once it is set up.

- With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

- A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

4. Final Filter

- A wide range of final filters (optional) is applicable to ensure ultrapure water without particles, bacteria or pyrogen.

5. Level sensor

- The tank integrated continuous level sensor measures water level within the tank and manages the system to start or stop producing water automatically based on requirements.

- Water level and quality inside the tank can be viewed from the control console.

Genie PURIST ultrapure water system produces Type I ultrapure water from RO, distilled or deionized water and it is designed for critical laboratory applications, offering desired solutions for research professionals who work with varieties of applications utilizing Type I ultrapure water in the lab. Quality of ultrapure water meet or exceeds ASTM, CLSI, CAP, and ISO Type I water standards.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via wired or wireless.

- An optional automatic system shut-off upon detection of any water leakage.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- A universal water level sensor can be provided to prevent the system from pumping air.

Effective TOC level controlment

- Built-in 185/254 nm dual wavelength lamp reduces TOC level in ultrapure water.

- On-line TOC monitor based on complete oxidation methods (for TOC models).

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. Cartridge

Ultra purification cartridge is filled with LeFilTM and OrganeFilTM media to remove trace ions and organics.

A full range of cartridges for various applications including ultra-low TOC, low Mg, low boron, ICP and DI type.

2. Control console

8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

The control console can be placed on the bench or inside a drawer for further flexibility and space saving.

The console screen and dispenser screens are water-frop proof. You can operate the console and dispenser with latex gloves on.

The system has two level password protection on display menu for safety purposes.

3. Dispenser

The volumetric function can automatically deliver the water volume you need once it is set up.

With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

4. Final Filter

Various final filters (optional) are applicable to ensure ultrapure water without particles, bacteria or pyrogen.

Genie A is a plug-and-play lab water system with small foot print, producing ultrapure water (Type I water) and RO water from tap water directly. It. It is an ideal choice for users who need up to 20 liters of ultrapure water or RO water per day. Quality of ultrapure product water meets or exceeds ASTM, CLSI, CAP, and ISO Type I water standards.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via wired cable or wireless.

- Automatic temperature compensation allows RO production rate stable over a wide range of temperature.

- Fully automated control system has cleaning, rising, flush and many other functions.

- System automatically rinses a new RO membrane. User does not need to set special rinse program for a new RO membrane.

- A bypath automatically sends the RO water to the drain if it does not meet a preset quality standard. The RO drain water is reused to increase the water yield thus it is more environmentally friendly.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- The Chlorine cleaning and pH cleaning functions keep the maintenance easier and ensure optimal water quality.

- No storage tank needed: eliminating potential contamination and bacteria growth from the storage tank.

- Compact design: no additional pre-treatment filters required; remote dispenser on the system.

- Leak protector incorporated can prevent damage from a water leakage by shutting the feed water off in case of unexpected leaking.

Effective TOC level controlment

- Built-in 185/254 nm dual wavelength lamp reduces TOC level in ultrapure water.

- On-line TOC monitor based on complete oxidation methods (for TOC models).

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. Cartridge

Pre-filtration pack removes most large particles, chlorine, calcium or organic compounds to protect RO membrane to extend their usable life.

Ultra purification cartridge is filled with LeFilTM and OrganeFilTM media to remove trace ions and organics.

2. Control console

8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

The control console can be placed on the bench or inside a drawer for further flexibility and space saving.

The console screen and dispenser screens are water-drop proof. You can operate the console and dispenser with latex gloves on.

The system has two level password protection on display menu for safety purposes.

3. Dispenser

The volumetric function can automatically deliver the water volume you need once it is set up.

With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

4. Final Filter

A wide range of final filters (optional) is applicable to ensure ultrapure water without particles, bacteria or pyrogen.

Genie E produces EDI water (Type II water) from tap water directly. Resistivity of the product water is above 5 MΩ•cm at 25 °C, which meets or exceeds Type II water quality as defined by ASTM, CAP, CLSI and ISO 3696 / BS 3997 and also complies with the purified water requirements from the European and U.S. Pharmacopoeia.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via CAN cable or wireless. “1+N” Mode.

- Exceptionally consistent and predictable high purity Type II water from the best-in-class EDI (electrodeionization) module.

- Stable RO permeability over a wide range of temperatures on account of a temperature stabilization feedback function of the module.

- An environmentally friendly In-line mercury-free germicidal UV lamp is applied to kill bacteria.

- A bypath automatically sends the RO water to the drain if it does not meet a preset quality standard. The RO drain water is reused to increase the water yield thus it is more environmentally friendly.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- Leak protector incorporated can prevent damage from a water leakage by shutting the feed water off in the event of unexpected leaking.

- Tank recirculation model guarantees water quality in the tank.

- Fully automated system has RO cleaning, pre-rinsing, flush and lots of other self-maintenance functions. The chlorine cleaning and pH cleaning functions make maintenance easier and ensure optimal water quality.

Effective TOC level controlment

- A tank sanitization module is equipped to effectively keep microbial growth at a lower level by LED UVC light.

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. EDI module

Internal EDI module removes the remaining ions, further reduces the content of organic compounds and has a certain capacity to prevent the growth of bacteria from RO water.

Ion exchange resins are continuously regenerated by an electric field. No hazardous chemical regeneration or costly resin replacement is needed.

EDI module has a high degree of automation and minimal electricity consumption by using the equivalent of energy.

2. Cartridge

Internal P Pack cartridge removes oxidants, organics, particles and scaling ions to prevent them from fouling the RO membranes and the EDI module.

AC Pack contains specially activated carbon to remove organic impurities and free chlorines.

3. Control console

8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

The control console can be placed on the bench or inside a drawer for further flexibility and space savings.

The console screen and dispenser screens are water-drop proof. You can operate the console and dispenser with latex gloves on.

The system has two level password protection on display menu for safety purposes.

4. Dispenser

The volumetric function can automatically deliver the water volume you need once it is set up.

With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

5. Final Filter

Various final filters (optional) are applicable to ensure ultrapure water without particles, bacteria or pyrogen.

6. Level sensor

The tank integrated continuous level sensor measures water level within the tank and manages the system to start or stop producing water automatically based on requirements.

Water level and quality inside the tank can be viewed from the control console.

Genie R produces reverse osmosis (RO) laboratory-grade water from tap water directly. It applies high recovery reverse osmosis (RO) technology to produce pure water for general laboratory needs with easy maintenance and low running costs. Genie R offers desired solutions for research professionals who work with a variety of applications utilizing RO pure water in the lab.

The system is CE/RoHS certified. RephiLe provides full document support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via wired or wireless. “1+N” Mode.

- Automatic temperature compensation allows RO production rate stable over a wide range of temperature.

- Fully automated control system has cleaning, rising, flush and many other functions.

- System automatically rinses a new RO membrane. User does not need to set special rinse program for a new RO membrane.

- A bypath automatically sends the RO water to the drain if it does not meet a preset quality standard. The RO drain water is reused to increase the water yield thus it is more environmentally friendly.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- The Chlorine cleaning and pH cleaning functions keep the maintenance easier and ensure optimal water quality.

- Leak protector is incorporated inside to shut the feed water off to prevent damage from leakage.

- A tank sanitization module can be used to effectively keep microbial growth at a lower level by LED UVC light.

- Tank recirculation model guarantees water quality in the tank.

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. Cartridge

Pre-filtration pack removes most large particles, chlorine, calcium or organic compounds to protect RO membrane to extend their usable life.

AC Pack contains special activated carbon to remove organic impurities and free chlorines.

2. Control console

8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

The control console can be placed on the bench or inside a drawer for further flexibility and space saving.

The console screen and dispenser screens are water-drop proof. You can operate the console and dispenser with latex gloves on.

The system has two level password protection on display menu for safety purposes.

3. Dispenser

The volumetric function can automatically deliver the water volume you need once it is set up.

With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

4. Level sensor

The tank integrated continuous level sensor measures water level within the tank and manages the system to start or stop producing water automatically based on requirements.

Water level and quality inside the tank can be viewed from the control console.

Genie G produces ultrapure water (Type I water) and EDI water (Type II water) from tap water directly. It offers desired solutions for research professionals who work with a variety of applications utilizing Type I ultrapure and Type II pure water in the lab. Quality of ultrapure water and EDI water meets or exceeds ASTM, CLSI, CAP, and ISO Type I water and Type II water standards, respectively.

The system is CE/RoHS certified. RephiLe provides full document support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via CAN cable or wireless. “1+N” Mode.

- Exceptionally consistent and predictable high purity Type II water from the best-in-class EDI (electrodeionization) module.

- Stable RO permeability over a wide range of temperatures on account of a temperature stabilization feedback function of the module.

- An environmentally friendly In-line Mercury-free germicidal UV lamp is applied to kill bacteria.

- A bypath automatically sends the RO water to the drain if it does not meet a preset quality standard. The RO drain water is reused to increase the water yield thus it is more environmentally friendly.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- Leak protector incorporated can prevent damage from a water leakage by shutting the feed water off in the event of unexpected leak.

- Tank recirculation model guarantees water quality in the tank.

- Fully automated system has RO cleaning, pre-rinsing, flush and lots of other self-maintenance functions. The chlorine cleaning and pH cleaning functions keep the maintenance easier and ensure optimal water quality.

Effective TOC level control

- A 185/254 nm dual wavelength UV lamp reduces TOC level in ultrapure water.

- A tank sanitization module is equipped to effectively keep microbial growth at a lower level by LED UV light.

- On-line TOC monitoring is based on complete oxidation methods.

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. EDI module

- Internal EDI module removes the remaining ions, further reduces the content of organic compounds and has a certain capacity to prevent the growth of bacteria from RO water.

- Ion exchange resins are continuously regenerated by an electric field. No hazardous chemical regeneration or costly resin replacement is needed.

- EDI module has a high degree of automation and minimal electricity consumption by using the equivalent of energy.

2. Cartridge

- Internal P Pack cartridge removes oxidants, organics, particles and scaling ions to prevent them from fouling the RO membranes and the EDI module.

- AC Pack contains special activated carbon to remove organic impurities and free chlorines.

- Ultra purification cartridge is filled with LeFilTM and OrganeFilTM media to remove trace ions and organics.

3. Control console

- 8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

- The control console can be placed on the bench or inside a drawer for further flexibility and space savings.

- The console screen and dispenser screens are water-drop proof. You can operate the console and dispenser with latex gloves on.

- The system has two level password protection on display menu for safety purposes.

4. Dispenser

- The volumetric function can automatically deliver the water volume you need once it is set up.

- With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

- A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

5. Final Filter

- A wide range of final filters (optional) is applicable to ensure ultrapure water without particles, bacteria or pyrogen.

6. Level sensor

- The tank integrated continuous level sensor measures water level within the tank and manages the system to start or stop producing water automatically based on requirements.

- Water level and quality inside the tank can be viewed from the control console.

High-output EDI water system Large Genie E produces Type II EDI water for up to 60 liters per hour.

The Large Genie series is a mini high-output water purification system introduced by RephiLe. Despite its small size, Large Genie is capable of producing large volumes of purified water with reliable quality. It is an ideal solution for users who need large quantity high-quality pure water per day but have limited lab space. With a Large Genie, you can use your lab room more efficiently and enjoy numerous ancillary advantages associated with its small footprint. Most importantly, the system can potentially have a positive impact on your overall operational costs and help improve the profitability of your facility.

EDI product water from high-output EDI water system Large Genie E meets or exceeds Type II water quality as defined by ASTM, CAP, CLSI and ISO 3696 / BS 3997 and also complies with the Purified Water requirements from the European and U.S. Pharmacopoeia.

The system is CE/RoHS certified. RephiLe provides full documents support to meet users’ GMP, GSP, GAP, GCP, and GLP requirements.

Easy-to-place

- Built-in pretreatment pack including prefiltration, chlorine removal and anti-scaling media; Generally no extra pretreatment needed

- Placement flexibility-wall-mounted, on the bench or on top of a distribution module (optional)

- Modular design. Plug and play connections for quick install

Easy-to-track

- RFID tracking of consumables, RO membranes and accessories to ensure optimal system performance and provide users with real-time operational intelligence

- Enhanced data management stores up to two years of historical information for service and review

- The ability to export and print data and log-in requirements are built into the system

Easy-to-use

- “1+N mode” - one water system can drive N units of dispenser (Up to 10 now and can be upgraded further more).

- A RephiBio filter can be embraced to produce pyrogen, nuclease and bacteria free water for critical applications.

Easy-to-control

- Large Genie equips with multiple touch screens which are highly responsive, water-drop proof, latex glove friendly, and perfect for wet labs.

- Intuitive display with comprehensive data views. No need to use additional paperwork or operating checklists.

- 9 display languages for selection

- RephiLink Mobile App enables remote control of the systems

Easy-to-maintain

- No tools are needed for system maintenance and simple service.

- Automatic system shut-off upon detection of any water leakage

Main Parts

RO Membrane:

- Stable RO permeability over a wide range of water temperatures

- Optimized RO-reject water recovery loop to maximize water efficiency

- Specially made RO pack with increased flow rates and reduced size

EDI Module:

- Exceptionally stable in producing high quality Type II water

- Consistently and predictably remove ionic species, including weakly ionized species

- A chemical-free process, free of safety, regulatory and environmental concerns

Tank:

- Consistent and accurate tank water level monitoring with a built-in continuous liquid level sensor in the storage tank

- Optional tank recirculation model guarantees water quality in the tank

- Mercury-free germicidal UV LED (265 nm) lamp equipped in tank sanitization module

Main Components

1. Control Console

- 8-inch touch screen with highly intuitive navigation program, allowing total control and easy operation of the system

- Comfortable viewing and operation with built in viewing angle and flexible placement by users

- Operable with gloves and wet hands

- Robust screen: easy to clean, resistant to scratches

2. Remote Dispenser

- Manual and volumetric dispensing, adjustable dispensing rate, and water quality monitoring

- Ergonomic dispenser allowing one-handed operation and control

- Operable with gloves and wet hands

- Height adjustable and 360 degree rotatable on an anti-skid base

3. Cartridges

- Improved stability of water quality & efficiency of polishing resins due to optimized flow design

- High pressure rated housings, proprietary sealing, and double O-ring design ensuring operational confidence

- A worry-free installation with two verifications: labels and RFID recognition

4. Reservoir

- 30-350 liters separate tank available for selection. Smooth inner surface to minimize biofilm formation and algal growth

- Provision for easy cleaning and fully drainable; Spray ball installation for efficient, effective and dependable cleaning

- Unique reinforcing-bar design to prevent deformation

High-output lab water system Large Genie R produces reverse osmosis (RO) laboratory-grade water from tap water directly for up to 80 liters per hour.

The Large Genie series is a mini high-output lab water purification system introduced by RephiLe. Despite its small size, Large Genie is capable of producing large volumes of purified water with reliable quality. It is an ideal solution for users who need large quantity high-quality pure water per day but have limited lab space. With a Large Genie, you can use your lab room more efficiently and enjoy numerous ancillary advantages associated with its small footprint. Most importantly, the system can potentially have a positive impact on your overall operational costs and help improve the profitability position of your facility.

Easy-to-place

- Built-in pretreatment pack including prefiltration, chlorine removal and anti-scaling media; generally, no extra pretreatment needed

- Placement flexibility-wall-mounted, on the bench or on top of a distribution module (optional)

- Modular design. Plug and play connections for quick installation

Easy-to-track

- RFID tracking of consumables, RO membranes and accessories to ensure optimal system performance and provide users with real-time operational intelligence

- Enhanced data management stores up to two years of historical information for service and review

- The ability to export and print data and log-in requirements are built into the system

Easy-to-use

- “1+N mode” - one water system can drive N units of dispenser (Up to 10 now and can be upgraded further more).

- A RephiBio filter can be used to produce pyrogen, nuclease and bacteria free water for critical applications.

Easy-to-control

- Large Genie is equipped with multiple touch screens that are highly responsive, water-drop proof, latex glove friendly, and perfect for wet labs.

- Intuitive display with comprehensive data views. There is no need to use additional paperwork or operating checklists.

- 9 display languages for selection

- RephiLink Mobile App enables remote control of the systems

Easy-to-maintain

- No tools are needed for system maintenance and simple service.

- Automatic system shuts-off upon detection of any water leakage

Main Parts

RO Membrane:

- Stable RO permeability over a wide range of water temperatures

- Optimized RO-reject water recovery loop to maximize water efficiency

- Specially made RO pack with increased flow rates and reduced size

Tank:

- Consistent and accurate tank water level monitoring with a built-in continuous liquid level sensor in the storage tank

- Optional tank recirculation model guarantees water quality in the tank

- Mercury-free germicidal UV LED (265 nm) lamp equipped in tank sanitization module

Main Components

1. Control Console

- 8-inch touch screen with highly intuitive navigation program, allowing total control and easy operation of the system

- Comfortable viewing and operation with built in viewing angle and flexible placement by users

- Operable with gloves and wet hands

- Robust screen: easy to clean, resistant to scratches

2. Remote Dispenser

- Manual and volumetric dispensing, adjustable dispensing rate, and water quality monitoring

- Ergonomic dispenser allowing one-handed operation and control

- Operable with gloves and wet hands

- Height adjustable and 360 degree rotatable on an anti-skid base

3. Cartridges

- Improved stability of water quality & efficiency of polishing resins due to optimized flow design

- High pressure rated housings, proprietary sealing, and double O-ring design ensure operational confidence

- A worry-free installation with two verifications: labels and RFID recognition

4. Reservoir

- 30-350 liters separate tank available for selection. Smooth inner surface to minimize biofilm formation and algal growth

- Provision for easy cleaning and fully drainable; Spray ball installation for efficient, effective and dependable cleaning

- Unique reinforcing-bar design to prevent deformation

NuZar water system set, U24 produces ultrapure water (Type I water) and RO water from tap water directly. The quality of ultrapure water meets or exceeds ASTM, CLSI, CAP, and ISO Type I water standards.

The NuZar water purification systems are compact and powerful. They are specifically designed for laboratories that demand a balance between the cost of ownership and exceeding their purified water requirements.

The system is CE/RoHS certified. RephiLe provides full document support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Feed: tap water

Product: Type I and RO Water

RO Makeup rate: 24 lph

NuZar U24 Set System includes:

- Main system

- RO membrane

- UV preinstalled

- NuZar P, H and U Pack cartridges and a 0.2 um final filter

- Cleaning Pack

- 10L tank preinstalled

- Tank vent filter RATANKVN7

- Leak protector

Optional: 30l, 60l, 100l or 350l tank

What to expect from NuZar U24?

Simple installation and maintenance

- RFID tracking of consumables (RO Pack included) for enhanced management

- Easy to remove consumable access cover.

- Automatic RO membrane cleaning cycles (Cl2 and pH cleaning)

- Mercury-free germicidal UVC LED lamp preinstalled in tank sanitation module

Reliable water quality and stable system performance

- Automatic hourly recirculation of ultrapure water

- Stable RO permeability over a wide range of temperatures

- Diversion to drain if quality of RO permeate falls below a pre-set set-point

Data traceability

- Automatic data backup for up to 2 years

- Easy data transfer through multiple interfaces, such as LAN, USB, etc.

Low running costs

- Environmentally friendly. High recovery rate

- Self-maintenance functions for maximum RO membrane effectiveness and lifetime

- RFID record of cartridge history for predictable consumable replacements

- Highly-efficient cartridge

Compact and small footprint

- An in-built single pretreatment P Pack

- Placement flexibility: on the bench or on a wall

- All-in-one design. Space-Saver

Main Components

- Cartridge

- Optimized flow design to improve water quality stability & efficiency of polishing resins

- High pressure rated housings, proprietary sealing, and double O-ring design ensures operational confidence

- Cartridge color, label, and RFID recognition prevent incorrect installation

- Ergonomic dispenser with 2.4″ color touch screen

- Two dispensers for one system

- Intuitive display: water quality with temperature compensation, volumetric dispensing and flow rate

- System alerts are displayed on the touch screen

- Effortless adjustment: dispensing rate (up to 2 L/min), manual and volumetric dispensing

- Choice of final filters: RephiBio and 0.2 μm final filter

- Two dispenser heights for the ultimate in flexibility

- Storage Tank

- A 10 liter integrated HDPE tank equipped with a sanitization module, mercury-free germicidal UVC LED lamp (peak emission wavelength at 265 nm) preinstalled.

- Extendable to 30/60/100/350 L tank (with mercury-free tank sanitization module) if needed.

NuZar water system set, Q produces ultrapure water (Type I water) from RO, distilled or deionized water. Quality of ultrapure water meets or exceeds ASTM, CLSI, CAP, and ISO Type I water standards.

The NuZar water purification systems are compact and powerful. They are specifically designed for laboratories that demand a balance between cost of ownership and exceeding their purified water requirements.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Feed: purified water

Product: Type I Water

Dispense rate: up yo 2 lpm

NuZar Q water system set includes:

- Main system

- UV preinstalled

- NuZar H and U Pack cartridges and a final filter.

What to expect from NuZar U24?

Simple installation and maintenance

- RFID tracking of consumables for enhanced management

- Easy to remove consumable access cover.

Reliable water quality and stable system performance

- Automatic hourly recirculation of ultrapure water

Data traceability

- Automatic data backup for up to 2 years

- Easy data transfer through multiple interfaces, such as LAN, USB, etc.

Low running cost

- Environmentally friendly. High recovery rate

- RFID record of cartridge history for predictable consumable replacements

- Highly-efficient cartridge

Compact and small footprint

- Placement flexibility - on the bench or on a wall

- All-in-one design. Space-Saver

Main Components

- Cartridge

- Optimized flow design to improve water quality stability & efficiency of polishing resins

- High pressure rated housings, proprietary sealing, and double O-ring design ensure operational confidence

- Cartridge color, label, and RFID recognition prevent incorrect installation

- Ergonomic dispenser with 2.4″color touch screen

- One dispenser for one system

- Intuitive display - water quality with temperature compensation, volumetric dispensing and flow rate

- System alerts are displayed on the touch screen

- Effortless adjustment - dispensing rate (up to 2 L/min), manual and volumetric dispensing

- Choice of final filters: RephiBio and 0.2 μm final filter

- Two dispenser heights for the ultimate in flexibility

- Storage Tank

- A submersible level sensor can be added to the feed water tank if needed

NuZar water system set, E10 produces EDI water (Type II water) from tap water directly.

The NuZar water purification systems are compact and powerful. They are specifically designed for laboratories that demand a balance between cost of ownership and exceeding their purified water requirements.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Feed: tap water

Product: Type II Water

EDI makeup rate: 10 lph

NuZar E 10 Set includes:

- Main system

- RO membrane

- 10L tank preinstalled

- Tank vent filter

- NuZar AC and P Pack cartridges

- Cleaning Pack

- Leak protector

Optional: 30l, 60l, 100l or 350l tank

What to expect from NuZar E10?

Simple installation and maintenance

- RFID tracking of consumables (RO Pack included) for enhanced management

- Easy to remove consumable access cover.

- Automatic RO membrane cleaning cycles (Cl2 and pH cleaning)

Reliable water quality and stable system performance

- Stable RO permeability over a wide range of temperatures

- Diversion to drain if quality of RO permeate falls below a pre-set set-point

- Mercury-free germicidal UVC LED lamp preinstalled in tank sanitation module

Data traceability

- Automatic data backup for up to 2 years

- Easy data transfer through multiple interfaces, such as LAN, USB, etc.

Low running cost

- Environmentally friendly. High recovery rate

- Self-maintenance functions for maximum RO membrane effectiveness and lifetime

- RFID record of cartridge history for predictable consumable replacements

- Highly-efficient cartridge

Compact and small footprint

- An in-built single pretreatment P Pack

- Placement flexibility - on the bench or on a wall

- All-in-one design. Space-Saver

Main Components

- Cartridge

- Optimized flow design to improve water quality stability & efficiency of polishing resins

- High pressure rated housings, proprietary sealing, and double O-ring design ensures operational confidence

- Cartridge color, label, and RFID recognition prevent incorrect installation

- Ergonomic dispenser with 2.4″color touch screen

- One dispensers for one system

- Intuitive display - water quality with temperature compensation, volumetric dispensing and flow rate

- System alerts are displayed on the touch screen

- Effortless adjustment - dispensing rate (up to 2 L/min), manual and volumetric dispensing

- Choice of final filters: 0.2 μm final filter

- Two dispenser heights for the ultimate in flexibility

- Storage Tank

- A 10 L integrated HDPE tank equipped with sanitization module, mercury-free germicidal UVC LED lamp (peak emission wavelength at 265 nm) preinstalled.

- Extendable to 30/60/100/350 L tank (with mercury-free tank sanitization module) if needed.

NuZar water system set, R24 produces reverse osmosis (RO) water from tap water directly. It offers desired solutions for research professionals who work with a variety of applications utilizing RO pure water in the lab.

The NuZar water purification systems are compact and powerful. They are specifically designed for laboratories that demand a balance between the cost of ownership and exceeding their purified water requirements.

The system is CE/RoHS certified. RephiLe provides full document support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Feed: tap water

Product: RO Water

RO Makeup rate: 24 lph

NuZar U24 Set System includes:

- Main system

- RO membrane

- 10L tank preinstalled

- Tank vent filter

- NuZar P Pack cartridge

- Leak protector

What can we expect from NuZar U24?

Simple installation and maintenance

- RFID tracking of consumables (RO Pack included) for enhanced management

- Easy to remove consumable access cover.

- Automatic RO membrane cleaning cycles (Cl2 and pH cleaning)

Reliable water quality and stable system performance

- Stable RO permeability over a wide range of temperatures

- Diversion to drain if quality of RO permeate falls below a pre-set set-point

- Mercury-free germicidal UVC LED lamp preinstalled in tank sanitation module

Data traceability

- Automatic data backup for up to 2 years

- Easy data transfer through multiple interfaces, such as LAN, USB, etc.

Low running cost

- Environmentally friendly. High recovery rate

- Self-maintenance functions for maximum RO membrane effectiveness and lifetime

- RFID record of cartridge history for predictable consumable replacements

- Highly-efficient cartridge

Compact and small footprint

- An in-built single pretreatment P Pack

- Placement flexibility - on the bench or on a wall

- All-in-one design. Space-Saver

Main Components:

Cartridge

- Optimized flow design to improve water quality stability & efficiency of polishing resins

- High pressure rated housings, proprietary sealing, and double O-ring design ensures operational confidence

- Cartridge color, label, and RFID recognition prevent incorrect installation

Ergonomic dispenser with 2.4″color touch screen

- Two dispensers for one system

- Intuitive display - water quality with temperature compensation, volumetric dispensing and flow rate

- System alerts are displayed on the touch screen

- Effortless adjustment - dispensing rate (up to 2 L/min), manual and volumetric dispensing

- Choice of final filters: 0.2 μm final filter

- Two dispenser heights for the ultimate in flexibility

Storage Tank

- A 10 L integrated HDPE tank equipped with sanitization module, mercury-free germicidal UVC LED lamp (peak emission wavelength at 265 nm) preinstalled.

- Extendable to 30/60/100/350 L tank (with mercury-free tank sanitization module) if needed.