What is a lab water system?

For most applications in a laboratory environment, the quality of domestic tab water is not sufficient. Think about the presence of high concentrations of ions, organic materials, particles (colloids) and micro-organisms. All these contaminants can influence the results of your analysis in the lab. A lab water system is a system that purifies water to the desired quality for your application by combining different purification techniques.

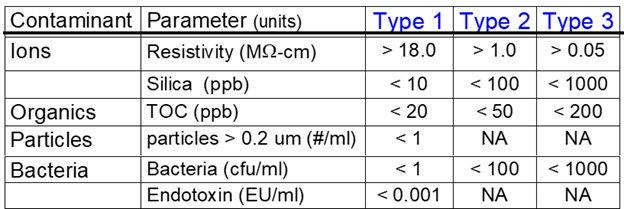

For laboratory applications 3 different types of water are defined based on their purity: type I, type II and type III.

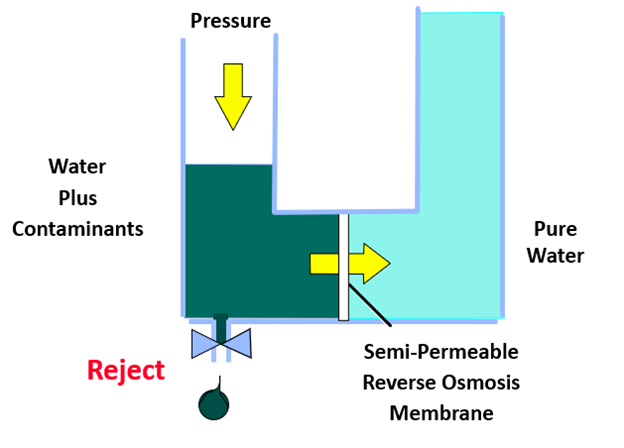

Type 3 water is also called reverse osmosis (RO) water or laboratory grade water. It is produced from tap water by applying 2 important purification techniques: pre-filtration and reverse osmosis. During the pre-filtration, the particle filters will capture all particles that have a larger dimension than the pores. Sometimes also activated carbon filters are used in the pre-filtration. These filters will capture mainly organic materials from the water by a process called adsorption. The most important component of RO systems is of course the Reverse Osmosis (RO) membrane. In this component the water is pumped through a semi-permeable membrane against the osmotic pressure. This step removes a large part of the contaminants via the waste water: ions, bacteria, colloids, organic material, pyrogens…

Typical applications for type III water are manual rinsing glassware, final rinse laboratory dishwashers, filling water baths, climate chambers, autoclaves,…

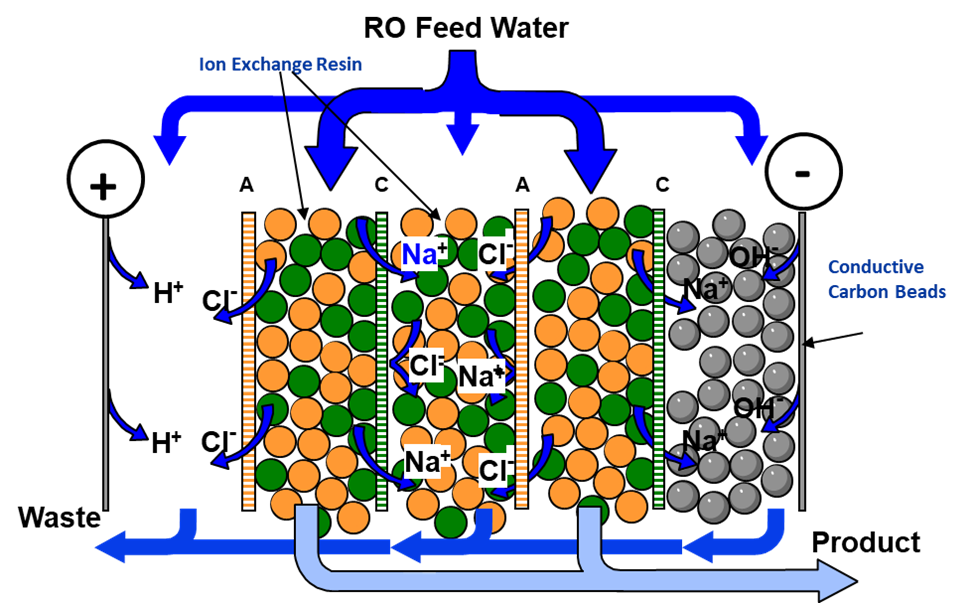

Type II water also is called EDI water, pure water, or analytical grade water. The first steps are in most cases the same as for type III water. This means that combo instruments that produce both type III and II from tab water are easy to produce. To purify water from type III water to type II water quality, in most cases 2 additional purification steps are applied: electrodeionization and UV irradiation. The electrodeionization (EDI) module is constructed as a resin column with a positive electrode, a negative electrode and multiple semi-permeable membranes. It will remove a very large part of the already reduced ion concentration. The UV lamp then will irradiate the water with light with wavelength 254 nm. UV light with this wavelength is very efficient against DNA. The UV light will therefore kill off all the micro-organisms and make the water sterile.

Typical applications for type II water are: buffers, pH solutions, culture media, clinical analyzers…

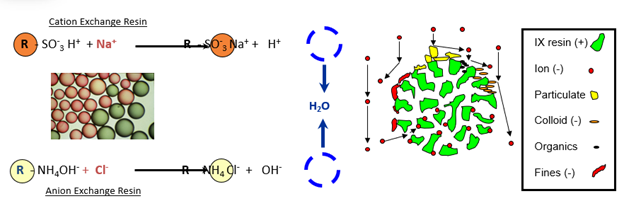

Type I water is also called ultrapure or reagent grade water. It can be produced by adding some additional filtration techniques on the techniques used for type II water, or it can also be produced directly from type III water. In practice for most applications, type I water is produced directly from type III water/ RO water. To produce type I water from type II or type III water, 3 additional purification steps are needed: a dual UV lamp, an ion exchange column, and a carbon filter. The UV lamp irradiates UV light at 2 wavelengths: 254 nm and 185 nm. The UV light with wavelength 254m will further kill off all micro-organisms and the UV light at 185 nm oxidize organic material without removing it. In the ion exchange column, the ion concentration will be further reduced. This column is built up from anion exchange resin and cation exchange resin. In the last step the oxidized organic material will be removed by the activated carbon filter.

Typical applications for type I water are: HPLC, GC, AA, ICP-MS, buffer solutions, culture media fur humane and animal cell culturing, reagents for molecular biology…

What solutions does Analis offer?

Analis is a distributor of Rephile water purification systems in Belgium and the Netherlands.

Ask our experts

Best solution for total cost of ownership

Best solution for flexibility and user comfort

Large production units

(Up to 500l/h):

Our products

Genie A is a plug-and-play lab water system with small foot print, producing ultrapure water (Type I water) and RO water from tap water directly. It. It is an ideal choice for users who need up to 20 liters of ultrapure water or RO water per day. Quality of ultrapure product water meets or exceeds ASTM, CLSI, CAP, and ISO Type I water standards.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via wired cable or wireless.

- Automatic temperature compensation allows RO production rate stable over a wide range of temperature.

- Fully automated control system has cleaning, rising, flush and many other functions.

- System automatically rinses a new RO membrane. User does not need to set special rinse program for a new RO membrane.

- A bypath automatically sends the RO water to the drain if it does not meet a preset quality standard. The RO drain water is reused to increase the water yield thus it is more environmentally friendly.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- The Chlorine cleaning and pH cleaning functions keep the maintenance easier and ensure optimal water quality.

- No storage tank needed: eliminating potential contamination and bacteria growth from the storage tank.

- Compact design: no additional pre-treatment filters required; remote dispenser on the system.

- Leak protector incorporated can prevent damage from a water leakage by shutting the feed water off in case of unexpected leaking.

Effective TOC level controlment

- Built-in 185/254 nm dual wavelength lamp reduces TOC level in ultrapure water.

- On-line TOC monitor based on complete oxidation methods (for TOC models).

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. Cartridge

Pre-filtration pack removes most large particles, chlorine, calcium or organic compounds to protect RO membrane to extend their usable life.

Ultra purification cartridge is filled with LeFilTM and OrganeFilTM media to remove trace ions and organics.

2. Control console

8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

The control console can be placed on the bench or inside a drawer for further flexibility and space saving.

The console screen and dispenser screens are water-drop proof. You can operate the console and dispenser with latex gloves on.

The system has two level password protection on display menu for safety purposes.

3. Dispenser

The volumetric function can automatically deliver the water volume you need once it is set up.

With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

4. Final Filter

A wide range of final filters (optional) is applicable to ensure ultrapure water without particles, bacteria or pyrogen.

Genie E produces EDI water (Type II water) from tap water directly. Resistivity of the product water is above 5 MΩ•cm at 25 °C, which meets or exceeds Type II water quality as defined by ASTM, CAP, CLSI and ISO 3696 / BS 3997 and also complies with the purified water requirements from the European and U.S. Pharmacopoeia.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via CAN cable or wireless. “1+N” Mode.

- Exceptionally consistent and predictable high purity Type II water from the best-in-class EDI (electrodeionization) module.

- Stable RO permeability over a wide range of temperatures on account of a temperature stabilization feedback function of the module.

- An environmentally friendly In-line mercury-free germicidal UV lamp is applied to kill bacteria.

- A bypath automatically sends the RO water to the drain if it does not meet a preset quality standard. The RO drain water is reused to increase the water yield thus it is more environmentally friendly.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- Leak protector incorporated can prevent damage from a water leakage by shutting the feed water off in the event of unexpected leaking.

- Tank recirculation model guarantees water quality in the tank.

- Fully automated system has RO cleaning, pre-rinsing, flush and lots of other self-maintenance functions. The chlorine cleaning and pH cleaning functions make maintenance easier and ensure optimal water quality.

Effective TOC level controlment

- A tank sanitization module is equipped to effectively keep microbial growth at a lower level by LED UVC light.

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. EDI module

Internal EDI module removes the remaining ions, further reduces the content of organic compounds and has a certain capacity to prevent the growth of bacteria from RO water.

Ion exchange resins are continuously regenerated by an electric field. No hazardous chemical regeneration or costly resin replacement is needed.

EDI module has a high degree of automation and minimal electricity consumption by using the equivalent of energy.

2. Cartridge

Internal P Pack cartridge removes oxidants, organics, particles and scaling ions to prevent them from fouling the RO membranes and the EDI module.

AC Pack contains specially activated carbon to remove organic impurities and free chlorines.

3. Control console

8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

The control console can be placed on the bench or inside a drawer for further flexibility and space savings.

The console screen and dispenser screens are water-drop proof. You can operate the console and dispenser with latex gloves on.

The system has two level password protection on display menu for safety purposes.

4. Dispenser

The volumetric function can automatically deliver the water volume you need once it is set up.

With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

5. Final Filter

Various final filters (optional) are applicable to ensure ultrapure water without particles, bacteria or pyrogen.

6. Level sensor

The tank integrated continuous level sensor measures water level within the tank and manages the system to start or stop producing water automatically based on requirements.

Water level and quality inside the tank can be viewed from the control console.

Genie PURIST ultrapure water system produces Type I ultrapure water from RO, distilled or deionized water and it is designed for critical laboratory applications, offering desired solutions for research professionals who work with varieties of applications utilizing Type I ultrapure water in the lab. Quality of ultrapure water meet or exceeds ASTM, CLSI, CAP, and ISO Type I water standards.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via wired or wireless.

- An optional automatic system shut-off upon detection of any water leakage.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- A universal water level sensor can be provided to prevent the system from pumping air.

Effective TOC level controlment

- Built-in 185/254 nm dual wavelength lamp reduces TOC level in ultrapure water.

- On-line TOC monitor based on complete oxidation methods (for TOC models).

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. Cartridge

Ultra purification cartridge is filled with LeFilTM and OrganeFilTM media to remove trace ions and organics.

A full range of cartridges for various applications including ultra-low TOC, low Mg, low boron, ICP and DI type.

2. Control console

8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

The control console can be placed on the bench or inside a drawer for further flexibility and space saving.

The console screen and dispenser screens are water-frop proof. You can operate the console and dispenser with latex gloves on.

The system has two level password protection on display menu for safety purposes.

3. Dispenser

The volumetric function can automatically deliver the water volume you need once it is set up.

With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

4. Final Filter

Various final filters (optional) are applicable to ensure ultrapure water without particles, bacteria or pyrogen.

Genie U produces ultrapure water (Type I water) and RO water from tap water directly, it offers desired solutions for research professionals who work with varieties of applications utilizing Type I ultrapure and RO pure water in the lab. Quality of ultrapure water meet or exceeds ASTM, CLSI, CAP, and ISO Type I water standards.

The system is CE/RoHS certified. RephiLe provides full documents support to meet user’s GMP, GSP, GAP, GCP, GLP requirements.

Design & Functions

- The system can be linked to multiple dispensers via CAN cable or wireless. “1+N” Mode.

- Automatic temperature compensation allows RO production rate stable over a wide range of temperature.

- Fully automated control system has cleaning, rising, flush and many other functions.

- System automatically rinses a new RO membrane. Users do not need to set special rinse program for a new RO membrane.

- A bypath automatically sends the RO water to the drain if it does not meet a preset quality standard. The RO drain water is reused to increase the water yield thus it is more environmentally friendly.

- The main system can be tucked away to save precious bench space since it fits well to be wall-mounted, set on the shelf or under the sink.

- The Chlorine cleaning and pH cleaning functions keep the maintenance easier and ensure optimal water quality.

- Leak protector incorporated can prevent damage from a water leakage by shutting the feed water off in case of unexpected leaking.

- Tank recirculation model guarantees water quality in the tank.

Effective TOC level controlment

- Built-in 185/254 nm dual wavelength lamp reduces TOC level in ultrapure water.

- A tank Sanitization Module is equipped to effectively keep microbial growth at a lower level by LED UVC light.

- On-line TOC monitor based on complete oxidation methods (for TOC models).

Easy Operation and Maintenance

- Performance history, alarms and alerts information, maintenance data of consumables as well as key parts are logged and traceable from a simple RFID scan at installation.

- RFID tags ensure perfect placement of consumables and trace their performance.

- Water quality, operation parameters, the status of the system, dispensers, components, and peripheral devices are stored and displayed on the large color touch screen monitor.

- Signature verification for maintenance and service.

Cartridges and Parts

1. Cartridge

- Pre-filtration pack removes most large particles, chlorine, calcium or organic compounds to protect RO membrane to extend their usable life..

- AC Pack contains special activated carbon to remove organic impurities and free chlorines.

- Ultra purification cartridge is filled with LeFilTM and OrganeFilTM media to remove trace ions and organics.

2. Control console

- 8-inch console controls system and peripheral devices (Such as leak protector and tank sanitization module). All operations can be done on the console by touching the screen.

- The control console can be placed on the bench or inside a drawer for further flexibility and space saving.

- The console screen and dispenser screens are water-drop proof. You can operate the console and dispenser with latex gloves on.

- The system has two level password protection on display menu for safety purposes.

3. Dispenser

- The volumetric function can automatically deliver the water volume you need once it is set up.

- With the adjusting button on a control console or a dispenser, you can dispense water at the flow rate you need up to 2 liters per minute.

- A dispenser handle can be set on the dispenser stand, on the main system, or even hanging onto other places to free up maximum bench space.

4. Final Filter

- A wide range of final filters (optional) is applicable to ensure ultrapure water without particles, bacteria or pyrogen.

5. Level sensor

- The tank integrated continuous level sensor measures water level within the tank and manages the system to start or stop producing water automatically based on requirements.

- Water level and quality inside the tank can be viewed from the control console.