Working Principles of abrasion & friability testing

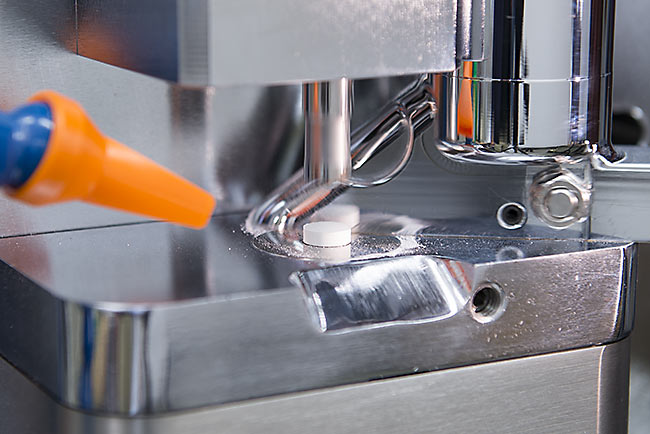

Erweka's TAR II instrument simulates the real-world conditions that tablets may encounter during manufacturing, packaging, and transportation.

The TAR II is the next step in intelligent, upgradeable friability & abrasion testing according to USP/EP/JP. Its unprecedented flexibility and intelligent features such as TestAssist and direct balance data transfer make TAR II the most advanced friability tester on the market.

Friability Testing

Measures the tendency of tablets to chip, crack, or break when subjected to mechanical stress, such as tumbling in a drum.

Abrasion Testing

Evaluates the wear and tear tablets may experience due to friction during handling and transportation.

The 7“ high resolution touch display with a modern user interface focuses the user on the most important task the TAR II has to fulfill - 100% USP/EP compliant friability testing. With the automatic calculation features of the TestAssist, the user is guided step-by-step through the testing process as quickly as possible and with its advanced balance connection feature, data is directly transmitted and calculated.

In addition to its ease of use, the TAR II is the most flexible friability tester we ever built. TAR II can be configured with one or two test stations and the optional intelligent balance feature - and the best part - all can also be upgraded at a later time point! A stand for the 10° position required by USP/EP is also included

Main Applications

Our Erweka instruments find applications across pharmaceutical and related industries, ensuring product quality and regulatory compliance:

Pharmaceuticals

Pharmaceuticals

Monitor the integrity and durability of tablets.

Research and Development

Research and Development

Optimize tablet formulations for stability and performance.

Quality Control

Quality Control

Ensure batch-to-batch consistency and adherence to regulatory standards.