Unlocking the Power of Tablet Testing

Explore the core pillars of our tablet testing expertise, covering Dissolution Testing, Tablet Physical Testing, and the All-Purpose Equipment.

Witness how ERWEKA raises the bar in pharmaceutical quality assurance.

Dissolution Testing

Dissolution testing, per USP standards in the pharmaceutical industry, evaluates how a drug dissolves in a simulated digestive environment. It ensures product quality, consistency, and bioavailability by measuring the rate and extent of drug release from a dosage form, typically using a paddle or basket apparatus.

ERWEKA is the only manufacturer worldwide to offer a complete range of manual and automated dissolution testers of all pharmacopeia methods, from USP 1, 2, 5, 6 dissolution testers to USP 3,7 Biodis, Flow-Through Cell USP 4 as well as chewing gum testers.

Physical Testing

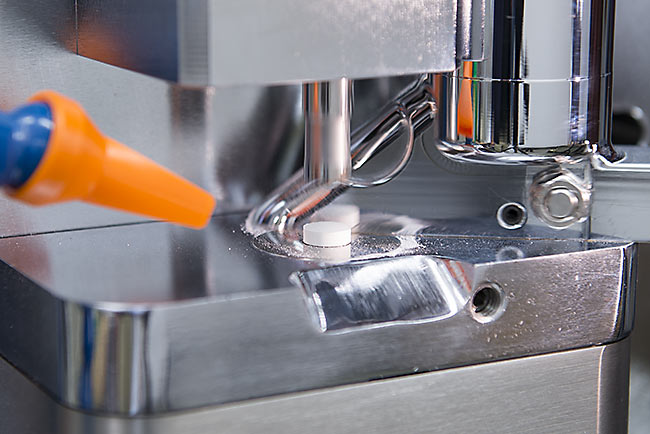

Tablet testing techniques, compliant with USP standards in pharmaceutical industries, include weight variation, hardness, friability, and disintegration tests. These tests ensure tablet quality, uniformity, durability, and timely dissolution, contributing to product effectiveness and safety.

Discover Erweka’s complete portfolio of tablet testing equipment supported by Analis in Belgium, the Netherlands and Luxemburg!

All-purpose equipment

Known as the "ERWEKA method", the modular All-Purpose Equipment is ideal for R&D formulation and small scale production in the pharmaceutical, chemical, cosmetic and food industry.

For development purposes and small batch production of tablets, ERWEKA offers its single punch eccentric tablet press EP-1: the ideal tool for R&D and small batch production up to 4000 tablets/hour.