What is a constant climate chamber?

Commercial products like pharmaceutics, cosmetics, electronics, food, packaging,… have changing properties under the influence of the environmental temperature, humidity and light over time. These changes can impact the quality and the functionality of these products. Environmental simulations research the effects of ambient climate using constant climate chambers to give recommendations for transport, storage and use. The environmental parameters temperature, humidity (RH) and light are simulated in constant climate chambers. A constant climate chamber is developed for the purpose of keeping the setpoints constant for longer periods. When changing the setpoint, the temperature change is relatively slow. From a technological point of view 2 technologies can be used: electrical heaters (combined with compressor technology) or Peltier.

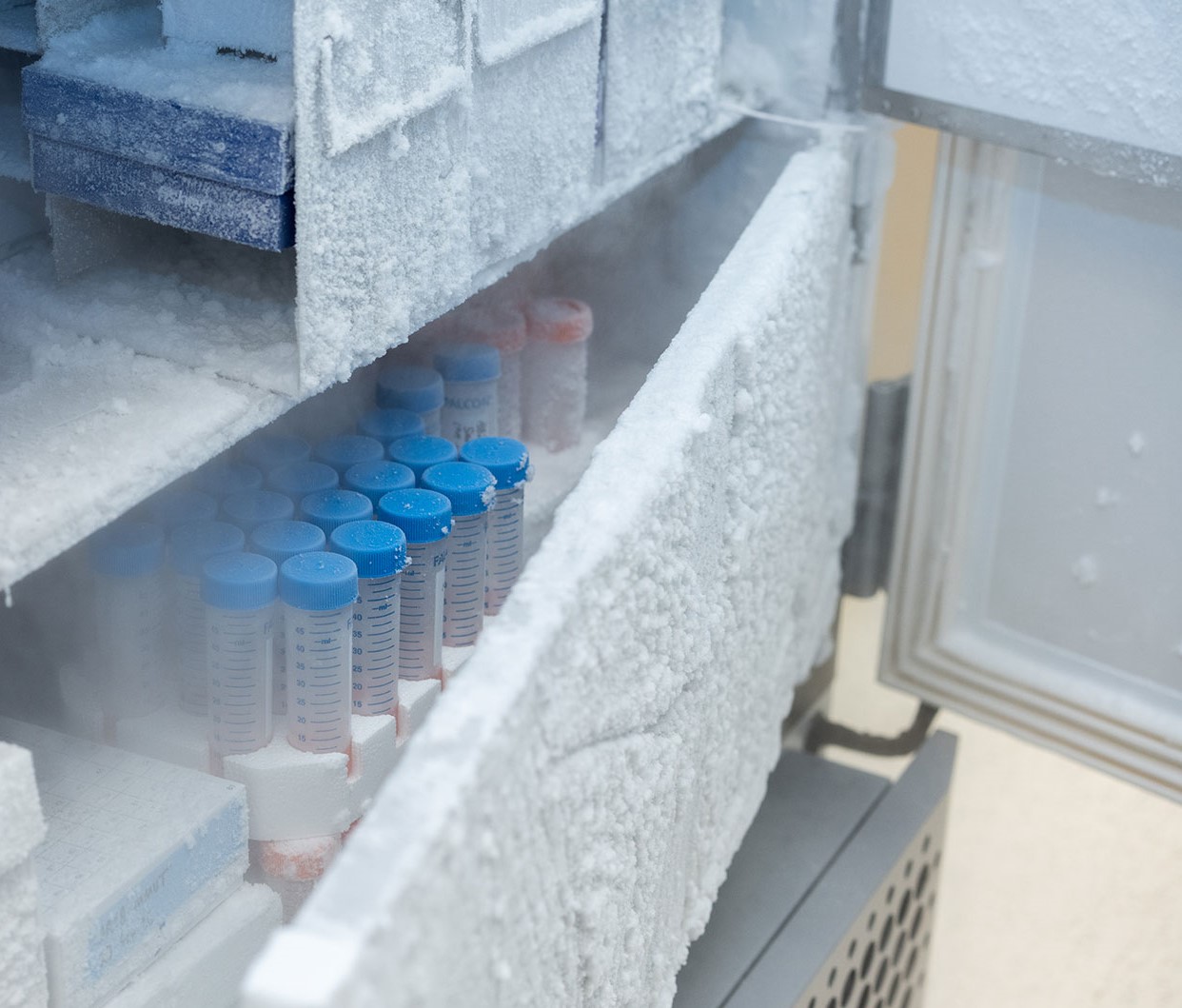

The most known application for a constant climate chamber is stability testing according to ICH (International Conference on Harmonisation). Other applications are pre-conditioning of samples, plant growth, insect growth,…

View products

When your setpoint is close to or below room temperature, the unit needs to have cooling technology included. This can either be done by integrating compressor cooling (combined with electrical heaters) or Peltier technology (single technology that can cool in both directions). When you are doing environmental simulations with constant climate conditions, Peltier has the following advantages over a compressor:

- Much lower energy consumption: up to 90% depending on the used setpoint

- Less vibrations and noise

- More compact: more chamber space for the same external dimensions

- Maintenance friendly: Peltier is very robust and doesn’t involve any cooling liquids

The ICH (International Conference on Harmonisation) guideline gives guidance on how to do stability testing. The aim of the ICH stability testing studies is to achieve information about:

- Expiration date of the finished pharmaceutical product

- Re-test period (expiration date of the active pharmaceutical ingredient)

- Selection of the correct excipients

- Storage temperature

- Necessary packaging components

- Handling during manufacture and transport

ICH includes 2 types of testing: long term testing and accelerated testing. Long term testing includes stability studies under the recommended storage condition for the re-test period or expiration date proposed for labeling. Accelerated testing includes exaggerated storage conditions to increase the rate of chemical degradation or physical change of API or FPP. The purpose is to determine long term effects under non-accelerated conditions (together with long term stability data) and to evaluate the effect of short-term excursions “out of storage conditions” (may occur during shipping).

What is a dynamic climate chamber?

A dynamic climate chamber is developed to program extreme and rapid temperature and humidity cycles, with the purpose to provoke accelerated ageing and destruction. When changing the setpoint, the temperature change is relatively fast (around 5°C per minute). From a technological point of view, strong electrical heaters are used combined with strong single our double compressor technology. For dynamic climate chambers, the focus lies more on industries like electro-technical industry, automotive, defense, materials, packaging,…

The objective is to determine:

- The lower and upper limits of destruction

- The climate range where functionality is guaranteed

- Latent design failures

- Conditions for transport, storage and intended use

- IEC 60068 provides guidance for dynamic environmental simulation tests.