The latest microwave reactors revolutionize reaction condition screening through parallel tests, elevating microwave-assisted synthesis. Since inception, they've accelerated experiments, yielding higher outputs. Widely adopted in pharmaceuticals, biotech, polymers, and agro-chemicals, with thousands installed globally, microwave synthesis is crucial for both organic and inorganic synthesis. The dedicated platform, with intuitive software, ensures precise control, saving time and effort in meeting specific synthesis demands.

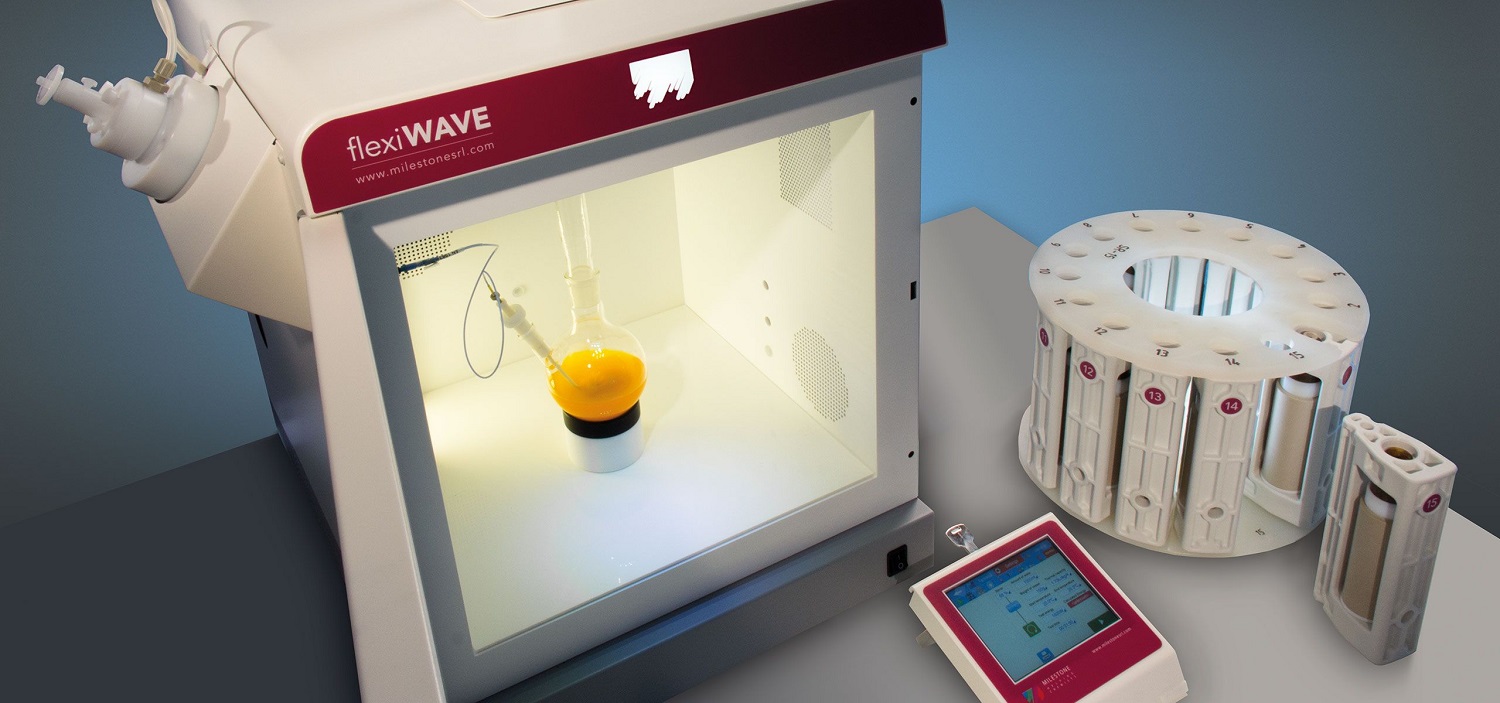

FLEXIWAVE Learn more

Timeless Glassware

The flexiWAVE is a highly versatile microwave platform designed to accommodate commonly used glassware. This approach provides exceptional adaptability, making the system suitable for a wide range of applications. The Timeless Glassware configuration, for instance, is ideal for comprehensive reaction optimization in research or educational settings. This innovative setup enables chemists to perform synthetic reactions under reflux conditions, rapidly enhancing traditional chemical processes conducted with hot plates, heating mantles, or oil baths through the integration of microwave technology.

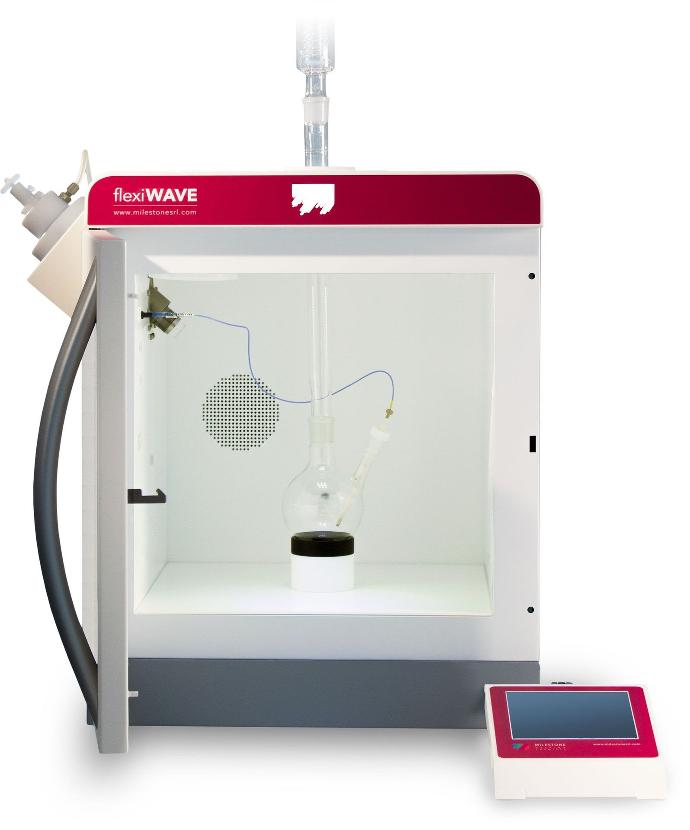

High-Pressure

Stubborn reactions, typically carried out in reflux with high-boiling solvents like xylenes, 1,2-dichlorobenzene, and N-methyl pyrrolidone, present challenges during workup, especially with increased reaction scale. The High-Pressure setup offers a solution by replacing traditional reflux devices, shifting from high-boiling to low-boiling solvents. This setup allows high-temperature reactions (up to 300 °C) with efficient temperature control using the easyTEMP sensor. Well-documented benefits include streamlined workup procedures and improved product purity. With the capacity for up to 15 high-pressure vessels concurrently, parallel synthesis becomes a viable and efficient choice.

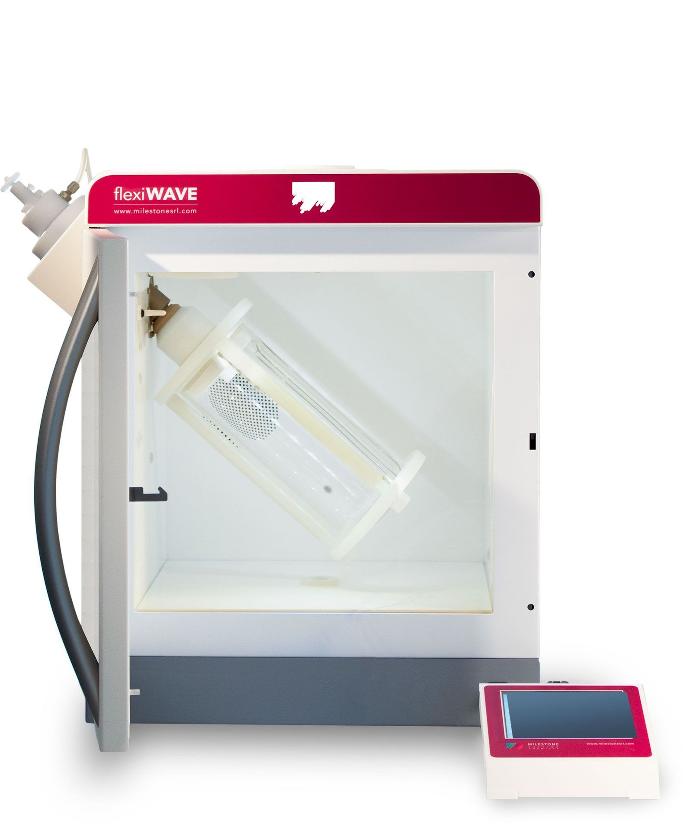

Solid-Phase

The Solid-Phase setup addresses challenges in heating and stirring heterogeneous mixtures, thick media, and solid-phase systems with conventional microwave instruments. Its innovative design includes the physical rotation of the reaction vessel for homogeneous heating, aided by a contact-less infrared sensor. The setup operates in normal atmosphere, inert gas, and vacuum, serving various processes like material functionalization, polycondensation, coating, and natural oil dehydration, making it a valuable tool for diverse chemical processes.

SYNTHWAVE

The Milestone synthWAVE boasts an unparalleled Single Reaction Chamber (SRC) patented technology, guaranteeing scalability, efficient reaction screening, and the highest temperature and pressure performance. Capable of handling single or multiple reactions at temperatures reaching 300 °C and pressures up to 199 bar, this system is remarkably user-friendly.

With the SRC technology, the synthWAVE empowers chemists to conduct large-scale batch and parallel reactions with unprecedented ease. The seamless transfer of small-scale synthesis methods to the SynthWAVE is facilitated, providing numerous advantages, including:

• Reduced reaction times (from hours to minutes)

• Improved yields

• Enhanced selectivity

• Low energy consumption

• A sustainable approach to synthesis

This innovative technology marks a significant advancement in high-pressure synthesis, offering efficiency and versatility for chemists across various applications.