- Analytical chemistry

- Automated Liquid Handling

- Capillary Electrophoresis

- Cell culture and Fermentation

- Cell health

- Centrifugation

- Chromatography (flash & prep)

- Cleaning

- Clinical Automation (TLA)

- Clinical IT solutions

- Clinical chemistry

- Clinical quality controls

- Color-Appearance and Physical tests

- DNA / RNA (Nucleic acids)

- Disinfection

- Electrochemistry

- Environmental monitoring

- Flow cytometry

- Flow cytometry Cell sorting

- Freeze drying

- Heating & cooling

- Hematology

- Imaging

- Immuno-Hematology

- Immunoassay

- In Vitro Fertilization (IVF)

- Lab furniture & design studies

- Liquid Handling (Manual)

- Mass spectrometers

- Material testing

- Metrology

- Microbiology (Clinical)

- Microscopy

- Moisture analysis

- Nephelometry

- POCT

- Particle characterization

- Platelet aggregation

- Protection cabinets

- Pumping

- Sample preparation

- Shakers and stirrers

- Sterilization

- Storage

- Synthesis

- Tablet testing

- Texture analyzers

- Toxicology

- Urine analysis

- Viscometry

- Water purification

- Weighing

- Material testing Oxidation stability

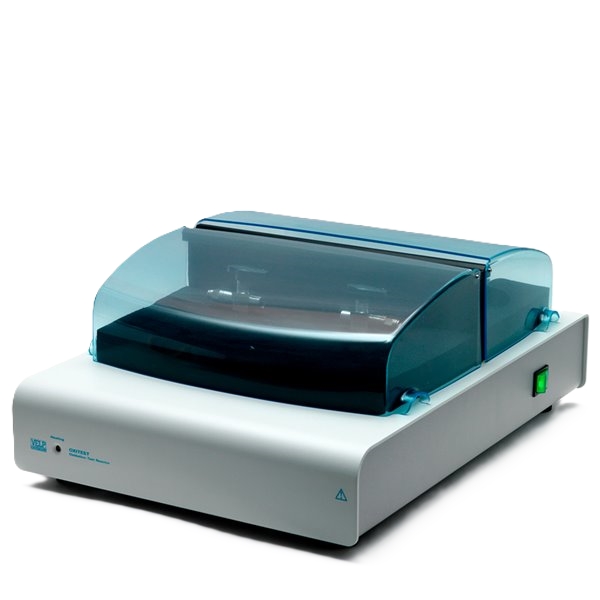

- OXITEST Oxidation Stability Reactor

HOME / APPLICATIONS & TECHNIQUES /

OXITEST Oxidation Stability Reactor

Reference: VEL-F30900248

https://www.analis.com/shop/vel-f30900248-oxitest-oxidation-stability-reactor-123386 https://www.analis.com/web/image/product.template/123386/image_1920?unique=689d05dFats and oils oxidation stability tests for R&D and QC Labs

The oxidation stability tests performed with the OXITEST reactor accelerate the lipid's oxidation process that in normal conditions can last weeks or months and provide fast, accurate and reliable results for Food & Feed, Cosmetic, Pharma and Petrochemical industries.

The OXITEST provides added value information for Quality Control and Research & Development Labs for:

- Quality control of raw materials and ingredients

- Transportation and effects on goods

- Storage period studies

- Product Development and behavior

- Formula Optimization

- Ingredient and alternative ingredients testing

- Process optimization

- Packaging study and alternative packaging comparison

The results of the OXITEST are expressed through the IP Induction Period.

The IP is the time required to reach the starting point of oxidation, corresponding to either a level of detectable rancidity or a sudden change in the rate of oxidation.

The longer the Induction Period, the higher the stability against oxidation over time.

Representative results testing the whole sample

The OXITEST reactor subjects the sample to a high oxidative stress environment in order to evaluate, in a short period of time, the resistance to fat oxidation:

- Established over-pressure of pure oxygen (6 bar, degree 5.0)

- High constant temperature, 90 °C

With the OXITEST Method, the stability test is performed directly on the sample as it is solid, liquid or doughy.

The method's key advantage is that the OXITEST ensures representative results without extensive sample preparation.

Other components of the sample matrix such as chemical oxidants or transition metal can promote oxidation and the use of extracted matter may not be a suitable predictor of stability.

OXISoft™ software powerful and intuitive

The OXITEST is entirely controlled via PC through the intuitive OXISoftTM software which is able to control up to 4 OXITEST simultaneously and independently. The OXISoft™ is quick and easy-to-use, at a glance you always have the program parameters, work conditions and results.

The software comes with multi-lingual support and a pre-installed library of methods related to a wide range of sample types, you can use these, modify them and create your own methods!

Data management, reportiing and archive with the following test types:

- Repeatability test

- Freshness test

- Formulas comparison

- Packaging comparison

- IP during ageing

- Estimated shelf life

Technical information

|

Number of oxidation chambers: |

2 |

|

Capacity single chamber: |

up to 100 ml |

|

Pressure range: |

0 - 8 bar |

|

Temperature range: |

from room temp. to 120 °C |

|

Max deviation from the set temperature |

≤ 0.5 °C |

|

Reproducibility of set temperature |

≤ ± 0.2 °C |

|

Interface: |

USB |

|

Connectivity |

Cloud via LAN or Wi-Fi |

|

Power |

900 W |

|

Power supply |

115 V / 60 Hz - 230 V / 50-60 Hz |

|

Weight: |

16.5 Kg (36.3 lb) |

|

Dimensions (WxHxD): |

365x190x485 mm (14.6x7.6x19.4 in) |

|

Overpressure |

Safety valve |

|

Out-range temperature |

Visual alarm |

|

Damaged probe |

Visual alarm |

Automated Liquid Handling

Capillary Electrophoresis

Cell culture and Fermentation

Cell health

Centrifugation

Chromatography (flash & prep)

Cleaning

Clinical Automation (TLA)

Clinical IT solutions

Clinical chemistry

Clinical quality controls

Color-Appearance and Physical tests

DNA / RNA (Nucleic acids)

Disinfection

Electrochemistry

Environmental monitoring

Flow cytometry

Flow cytometry Cell sorting

Freeze drying

Heating & cooling

Hematology

Imaging

Immuno-Hematology

Immunoassay

In Vitro Fertilization (IVF)

Lab furniture & design studies

Liquid Handling (Manual)

Mass spectrometers

Material testing

Metrology

Microbiology (Clinical)

Microscopy

Moisture analysis

Nephelometry

POCT

Particle characterization

Platelet aggregation

Protection cabinets

Pumping

Sample preparation

Shakers and stirrers

Sterilization

Storage

Synthesis

Tablet testing

Texture analyzers

Toxicology

Urine analysis

Viscometry

Water purification

Weighing

?unique=7252347)

?unique=7252347)