What is an ART workstation?

An ART (assisted reproduction technology) workstation or fertilisation cabinet is a cabinet type that is adjusted to work with gametes and/or embryos at near body temperature during in vitro fertilization (IVF). It can either be a vertical laminar flow or a biosafety cabinet, depending on the exact application and local regulations. It has heating zones built in the work tray to keep culture media at near body temperature. You can work with a paraffin or mineral oil layer on the culture, or with open culture. When working in open culture, the cabinet provides humidified gas to maintain gametes and embryos in a good working condition. Due to the gas mixture, the pH conditions of the buffered media can be maintained, and evaporation can be prevented without an overlay of mineral oil of paraffin. There is a stereomicroscope built in with heated glasses beneath to inspect culture dishes. ART workstations also have a built-in PC with a logger software. The main function is to keep a good surveillance of all probe measurements. The PC can also be used to display the camera image of the microscopes. Sometimes, also the fertilization cabinet has built-in incubators to provide temporary shelter of embryo’s during manipulation.

What is the difference between a vertical laminar flow and a biosafety cabinet ART workstation?

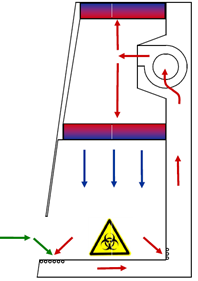

ART (assisted reproductive technology) workstations or fertilization cabinets can be both vertical laminar flow cabinets and biosafety cabinets. Vertical laminar flows are the most used type. A vertical laminar flow cabinet only offers a unidirectional downflow of clean air, providing a contaminant free work environment for the manipulation of gametes and embryos. The main advantage of using a vertical laminar flow type is that you have a much larger work opening.

![]() I

I

A biosafety cabinet on the other hand will also provide protection of the operator and the environment against the products used within the cabinet. It will create a negative pressure beneath the sash window to protect the operator against potential biohazards. In the top part of the cabinet, 70% of the air will be re-introduced in the cabinet trough a HEPA filter to protect the gametes and embryos against contaminations. 30% of the air will leave the cabinet through a HEPA filter on the top of the cabinet to create the inflow beneath the sash window (to protect the operator).

I

I

Not all ART workstations on the market have gas mixers. This is a unique feature of the Esco ART workstations. Users can select a simple CO2 gas mixture to control the CO2 concentration. Another possibility is a tri-gas mixture, where also the oxygen level is controlled. This way oocytes and embryos can safely be incubated for short periods in the integrated mini-incubators.

In the design of Esco ART workstations, the heating plates are divided into zones. The zones can be switched on and off individually. This is a huge help during vitrification where some solutions need to be kept at room temperature, while others need to be kept at body temperature.

Often, mini-incubators are required within the cabinet. With Esco ART workstation, there is the possibility to have them built in the work tray. This way you don’t loose any valuable work area. The number of built-in incubators depends on the size of the cabinet. 1m20 cabinets typically can have 2 built-in incubators, while 1m80 cabinets can have 3. Each incubator has a capacity of four 4-well dishes.