Optimize Microbial Screening with Beckman Coulter Microbioreactors

The stand-alone and integrated microbioreactors from Beckman Coulter Life Sciences help to accelerate the screening of microbial strains, media, and bioprocess conditions with real-time evaluations of biomass, fluorescence, pH value, dissolved oxygen, and other key cultivation parameters. Enjoy the benefits of automated sample draws and liquid transfers, easy data analysis, and increased walk-away time.

Harness Real-Time Insights with BioLector XT microbioreactor

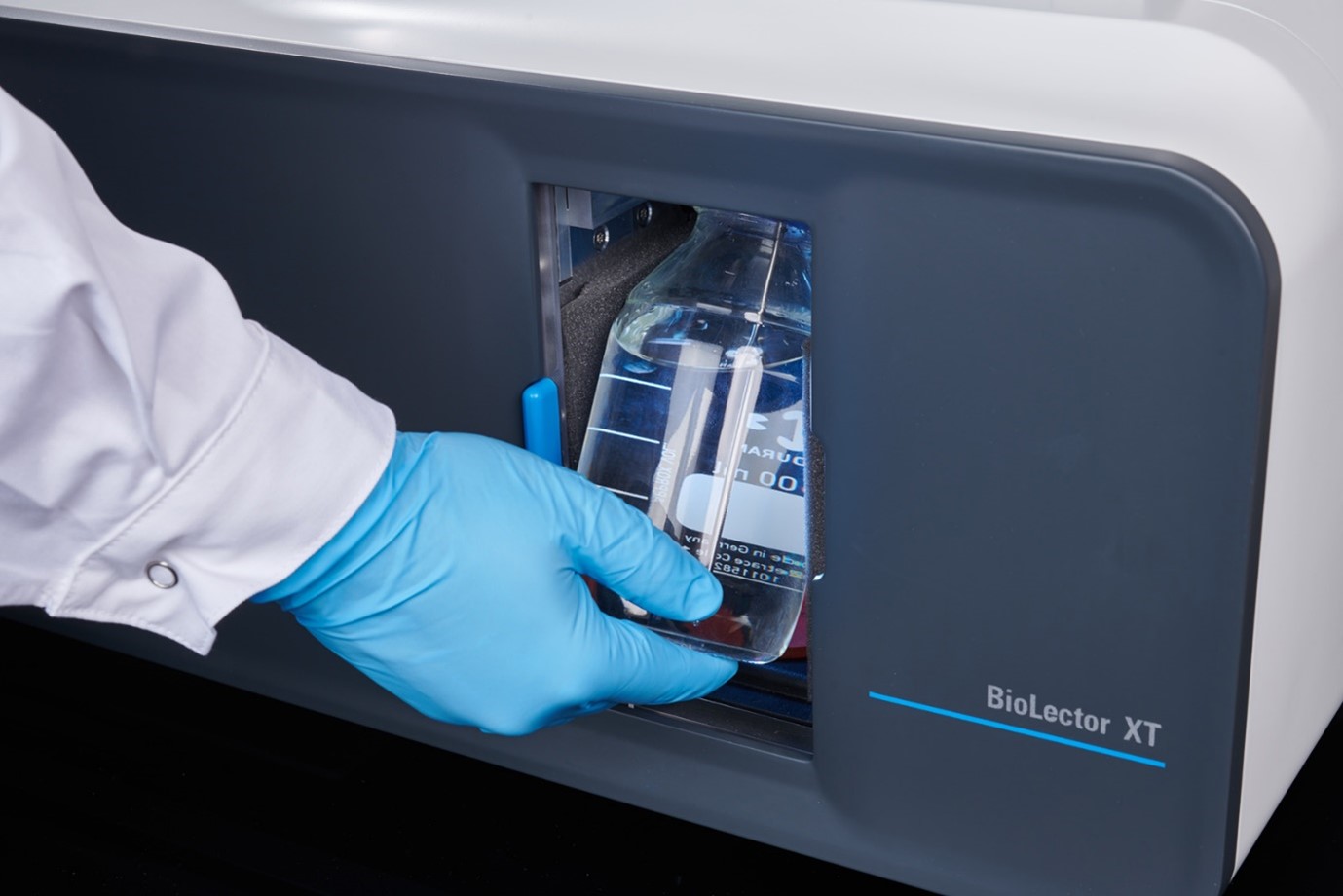

The BioLector XT microbioreactor enables real-time evaluation of biomass, fluorescence, pH, dissolved oxygen in the liquid phase (DO), and other key cultivation parameters for aerobic, anaerobic and phototrophic microorganisms.

Building on trusted BioLector Pro technology, the BioLector XT microbioreactor is based on a standard ANSI/SLAS (SBS) microtiter plate (MTP) format, and operates with online, pre-calibrated optical sensors. Disposable 48 well MTPs enable online measurement of cultivation parameters, while patented microfluidic technology supports simultaneous pH control and feeding. The optional microfluidic module eliminates manual liquid handling—no tubing or pipetting required, as everything is part of the gamma-radiated ready-to-use plate.

BioLector XT Microbioreactor & Biomek i5 Liquid Handler Integration

The integration of the BioLector XT microbioreactor and a Biomek i-Series liquid handler allows you to increase your walk-away time for microbial strain and process screening experiments by unlocking the full potential of an automated screening platform:

- Automated sampling / harvesting

- Automated inoculation of cultivation wells

- Automated induction

- Bolus feeding / repeated fed-batch

- Induction profiling

- Microbial growth synchronization

- Feed profiling

- Media preparation

- Automated upstream processing with microbial cultures

BioLector XT Video Overview

This video gives a comprehensive overview of the BioLector XT instrument and components. Watch the video gallery

Unlock the Advantages of our solutions for Your Business

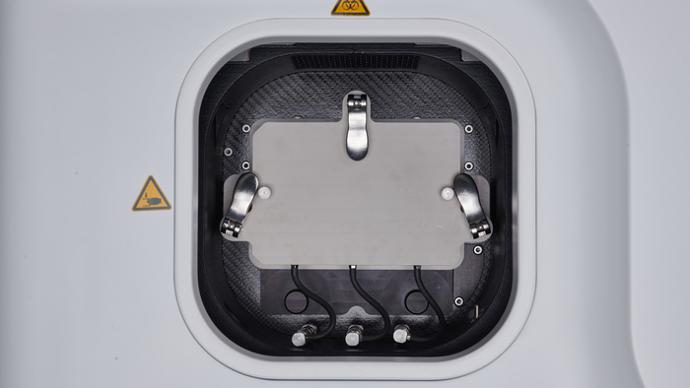

Innovative new gassing head

Enables fed-batch experiments under anaerobic conditions

Gassing with O2 within a range of 1%–100% and with CO2 within 1%–12%

Reduces gas consumption to a few mL/minute

Optional humidification of gases reduces evaporation

Optional microfluidic module

Unleash the full potential of the BioLector XT

Complements the online monitoring function with well-specific pH regulation/feeding

Enables the use of 2 reservoir wells per 4 cultivation wells

Microvalves allot liquids at the nanolitre scale

“Plug-and-play” plate design

Real-time kinetics out of 48/32 parallel cultivations

Customizable feeding strategies (batch, fed-batch, bolus, continuous)*

Control of pH on-the-plate with pre-calibrated optical sensors (*)

Small working volume (800 – 2400 μL)

(*) Functionality requires optional microfluidic module

Intelligent BioLection Software

Intuitive user interface supports multi-user environments

Free programming of all control parameters

Open system enables live data downloads

Fast processor ensures rapid download of experiment data

Advantages & Applications of the BioLector XT Microbioreactor

High-throughput microbioreactor enables real-time evaluation of biomass, fluorescence, pH, dissolved oxygen in the liquid phase (DO), and other key cultivation parameters for aerobes and anaerobes.

How microbioreactors for high-throughput cultivations accelerate your bioprocess development ?

Building on trusted BioLector Pro technology, the BioLector XT microbioreactor is based on a standard ANSI/SLAS (SBS) microtiter plate (MTP) format and operates with online, pre-calibrated optical sensors. Disposable 48-well MTPs enable online measurement of biomass, fluorescence, pH and DO, while patented microfluidic technology supports simultaneous pH control and feeding. The optional microfluidic module eliminates manual liquid handling—no tubing or pipetting is required, as everything is part of the gamma-radiated, ready-to-use plates.

Scale-up is the bottleneck in bioprocess development. It takes a lot of time, drastically slowing down early-stage development and thus the path to the final product. From early screening experiments in shake flasks over microbial cultivation in smaller fermentors to production scale, your processes can take days or weeks. You can, of course, reduce the time by using multiple fermentors simultaneously. But this is limited by your available space, human resources, and budget. Imagine how costly it would be to run 32, or even 48, parallel fermentations in sizable fermentors …

And now imagine if you could achieve such a throughput with only two hours of hands-on time.

What are the advantages of the BioLector microbioreactors for microbial cultivation ?

Up to 48 simultaneous fermentations in a single microtiter plate.

Comprehensive online monitoring of biomass (broad OD range), fluorescence, DO, and pH.

NEW: Precisely controllable oxygen supply from 0-100 % O₂ thanks to gas-tight lid*

Suitable for fed-batch cultivations (anaerobic or aerobic), thanks to well-individual pH and feeding control*.

Automatable for complex experiment designs (DoE), sampling, and more.

What Applications Can Benefit from Enhanced Cultivations?

Vaccine development

Fed-batch development*

pH profiling*

Feeding rate optimization*

Media screening and optimization

Optimization of cultivation parameters

Cell line and strain screening

Synthetic and systems biology

Anaerobic / aerobic / microaerophilic cultivations

Statistical design of experiments (DoE)

Growth characterization

High-throughput protein expression

Enzyme and cell activity tests

Functional genomics

Proteomic studies

Inhibition and toxicity tests

Quality control

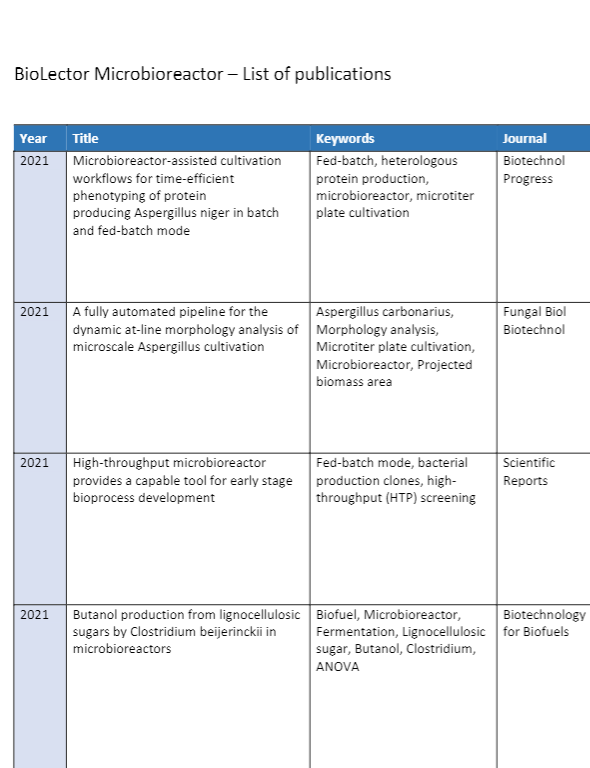

Explore In-Depth Insights: Application Notes and Publications

BioLector Microbioreactor List of Publications.

Anaerobic cultivation processes of probiotic bacteria in the BioLector XT microbioreactor.