NDA 702 Dumas Nitrogen Analyzer

Reference: VEL-F30800080

https://www.analis.com/shop/vel-f30800080-nda-702-dumas-nitrogen-analyzer-123393 https://www.analis.com/web/image/product.template/123393/image_1920?unique=689d05dThe perfect solution to maximize your productivity

NDA 702 Dumas elemental analyzer is the best solution for high throughput labs looking for a fast and safe analyzer with the possibility to choose between Helium and Argon as carrier gas.

The NDA 702 is powered by the DUMASoftTM software and produces N/Protein results in just 3 to 4 minutes totally unsupervised and cloud-enabled.

NDA 702 is dramatically faster, easier, and safer than a traditional Kjeldahl system.

The NDA 702 is a safe analyzer that does not require aggressive chemicals or time-consuming analysis steps, just prepare your sample and walk away!

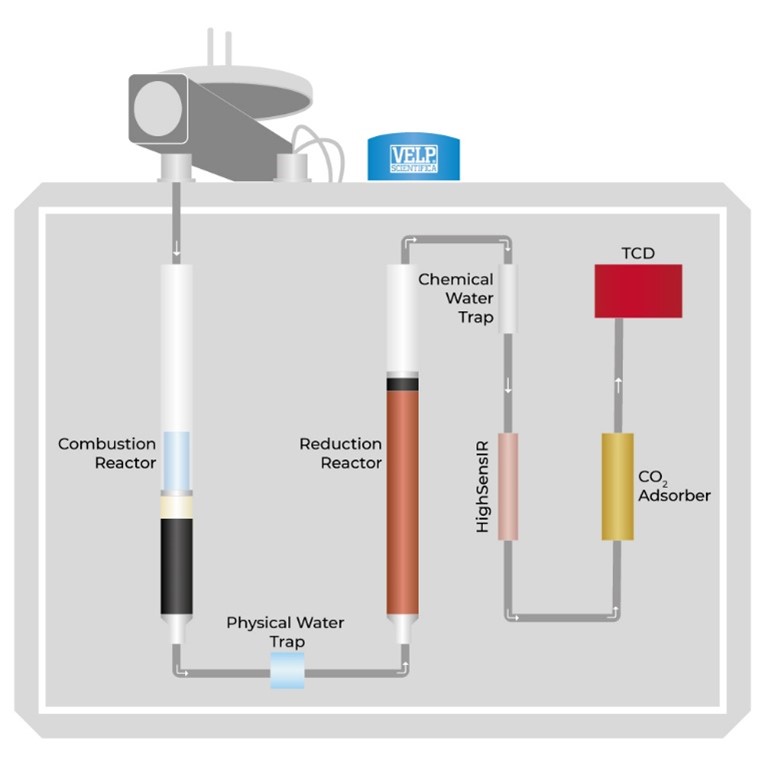

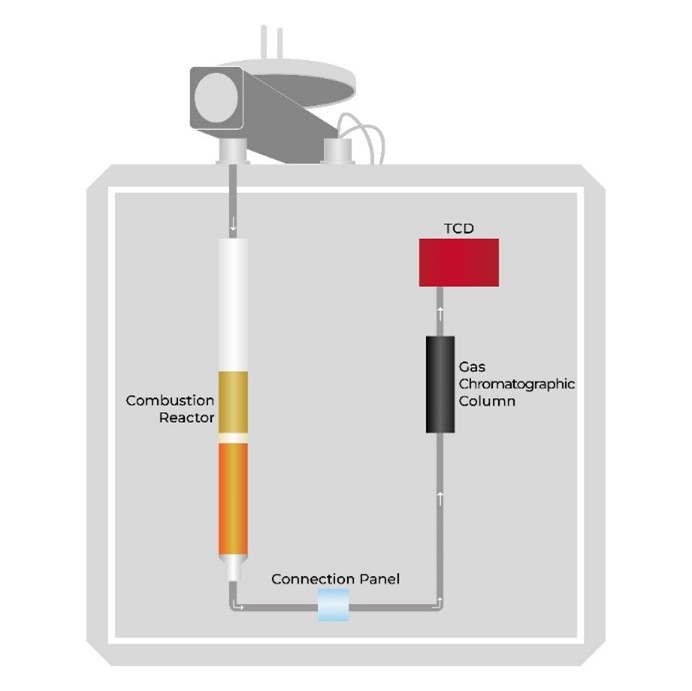

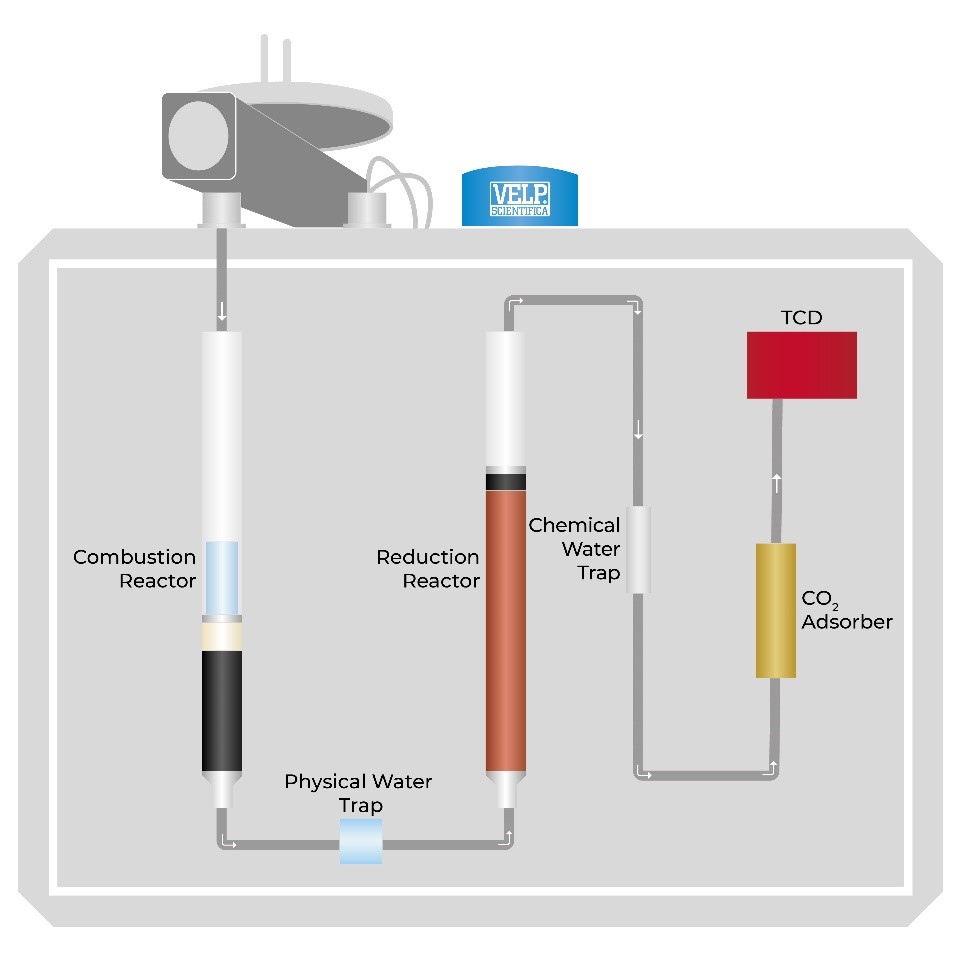

NDA 702 Nitrogen Analyzer Working Principle

The Dumas method starts with the combustion of the sample which takes place inside the VELP combustion furnace (CF) at a temperature higher than 1000°C to obtain elemental compounds.

Water separation is performed in 2 steps in the NDA 702. The first is the maintenance-free physical trap DriStep™ (WT1) strategically placed after combustion and the second is a chemical trap (WT2) that ensures the complete elimination of residual 1% of water.

Between the two traps, the flow of gases passes through the reduction furnace (RF) where NOX compounds are transformed into molecular nitrogen N2.

Afterwards, the CO2 is trapped by the unique self-regenerating VELP CO2 adsorbers.

At this point, elemental nitrogen is detected by the innovative thermal conductivity detector TCD LoGas™ which will send the data to DumaSoftTM to calculate the amount of Nitrogen and Protein.

Elemental Analysis and the Dumas Method

The Dumas method, also known as the combustion method, is a primary method of determination of Nitrogen and Protein ensuring fast results, ease of use, and safety. However, it is considered an alternative to the classical Kjeldahl method. In fact, both of the methods are validated by different international organizations: Kjeldahl is officially recognized by AOAC, EPA, DIN, ISO, etc., whilst Dumas by AOAC, AACC, ISO, DIN, ASBC, AOCS, OIV, etc. Nevertheless, in some countries, the local guidelines recommend one method rather than the other.

The Dumas method for nitrogen determination, developed in 1831, is older than the Kjeldahl, 1883, but more convenient in many aspects such as speed, safety, cleanliness, productivity, and cost per analysis.

The problem in the past was that it was not easy to reproduce the conditions required by the Dumas method and for this reason, the Kjeldahl technique took the lead and became considered as the classical method for nitrogen/protein determination.

Nowadays, thanks to steps forward in technology, the Dumas nitrogen determination is becoming more widespread.

Technical information

|

Method of analysis: |

Nitrogen determination according to Dumas method (combustion) |

|

Analysis time: |

3/4 minutes |

|

Detector: |

TCD (Thermal Conductivity Detector) |

|

Sample weight: |

Up to 1 g |

|

Autosampler type: |

Electronic |

|

Autosampler capacity: |

Up to 4 discs, 30 positions each (up to 117 samples) |

|

Detection range N: |

ppm up to 200 mg abs. (or 100 %) |

|

Reproducibility (RSD): |

< 0.5% for EDTA standards (9.57%N) |

|

Recovery: |

> 99.5% |

|

Combustion temperature: |

1100 °C / 2012 °F |

|

Carrier gas: |

Helium or Argon (grade 5.0) |

|

Combustion gas: |

Oxygen (grade 5.0) |

|

Connectivity |

Ermes Cloud Platform via Wi-Fi or LAN connected to a PC |

|

Interfaces: |

USB; RS232 |

|

Weight: |

54 kg / 119 lb |

|

Dimensions (WxHxD): |

655x510x410

mm (H 690 mm with autosampler) |

|

21 CFR part 11 compliance: |

Yes, optional package available |

|

Official references: |

ISO 16634; ISO 14891; AOCS Ba 4e-93, AOAC 992.23; AACC 46-30; ICC 167, ASBC Barley 7C; AOCS Ba 4f-00; AOAC 992.15; ASBC AOAC 997.09; OIV-MA-AS323-02A; AOAC 990.03; AOAC 993.13; ISO 13878; EN 16168, etc. |