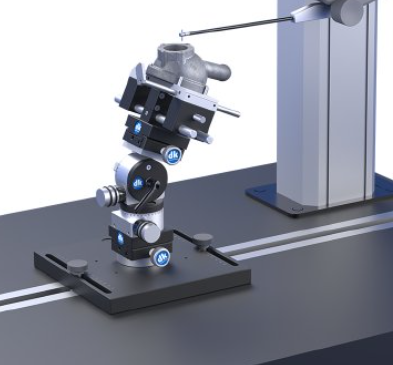

The Werth flexible configurability for individual workpieces, complete assemblies, metals, plastics or ceramics

Whether individual workpieces or complete assemblies, metals, plastics or ceramics, the flexible configurability of Werth coordinate metrology achieves the optimum solution for the respective applications. Punched parts, plastic injection moulded workpieces, tools and moulds, components with micro-structures or optical functional surfaces as well as 3D free-form workpieces are just a few examples.

With computed tomography, for example, plastic injection moulded parts or even complete assemblies can be captured completely and accurately, inside and out.

Typical application fields for Werth Multisensor Coordinate Measuring Machines can be found in medical technology, automotive engineering, mechanical engineering, the electronics industry, aerospace, the watchmaking industry and in many other areas of manufacturing.

PRODUCTION

PRODUCTION

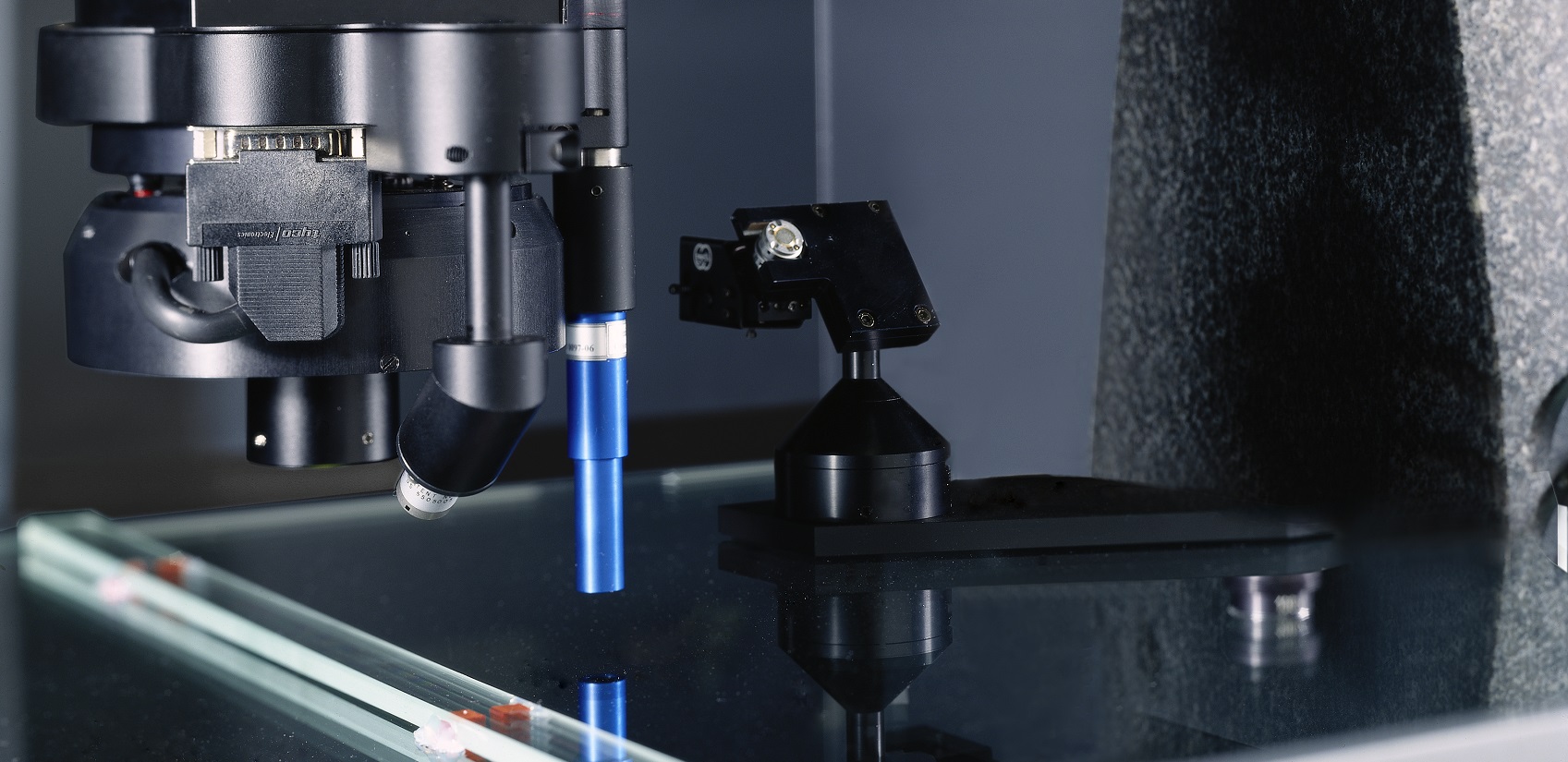

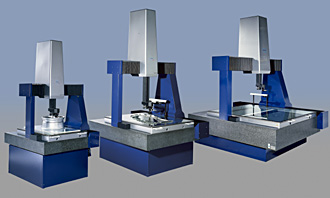

3D – CNC Multisensor machines with a fixed bridge

A wide variation of measuring

dimensions up to 3 meter and more with µm level precision

The ScopeCheck® series with integrated temperature compensation has been especially developed for use in the production environment.

Sensitive components such as scales and guideways are encapsulated or

covered to protect against contamination.

LABORATORY

LABORATORY

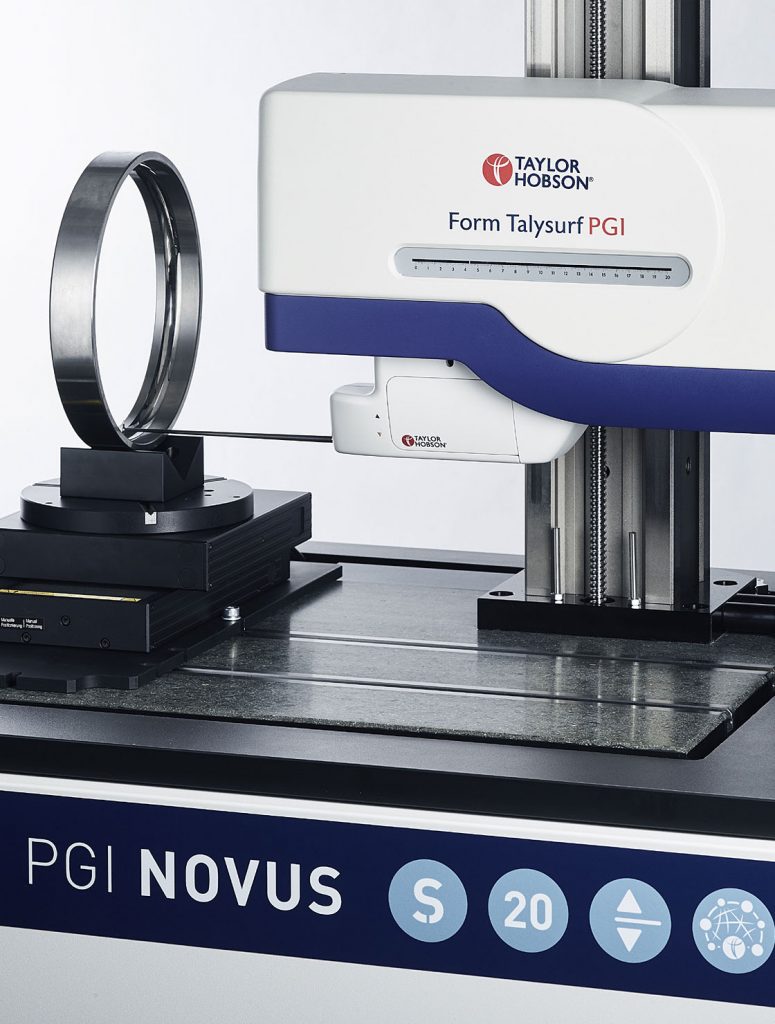

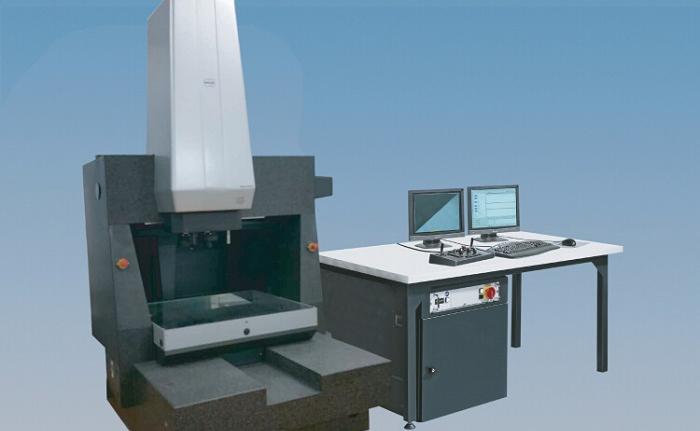

High-performance multi-sensor CMM for maximum accuracy in the lab

The Werth VideoCheck® series offers the perfect platform for solving demanding measuring tasks through precision mechanics and modern control technology.

Traceable length measurement errors down to the 1/10 µm range enable tactile and optical 3D measurements with the lowest measurement uncertainties (0,15µm). Due to the high basic accuracy, these machines are the ideal basis for a wide range of multi-sensor systems.

SHOPFLOOR & MEASURING ROOM

SHOPFLOOR & MEASURING ROOM

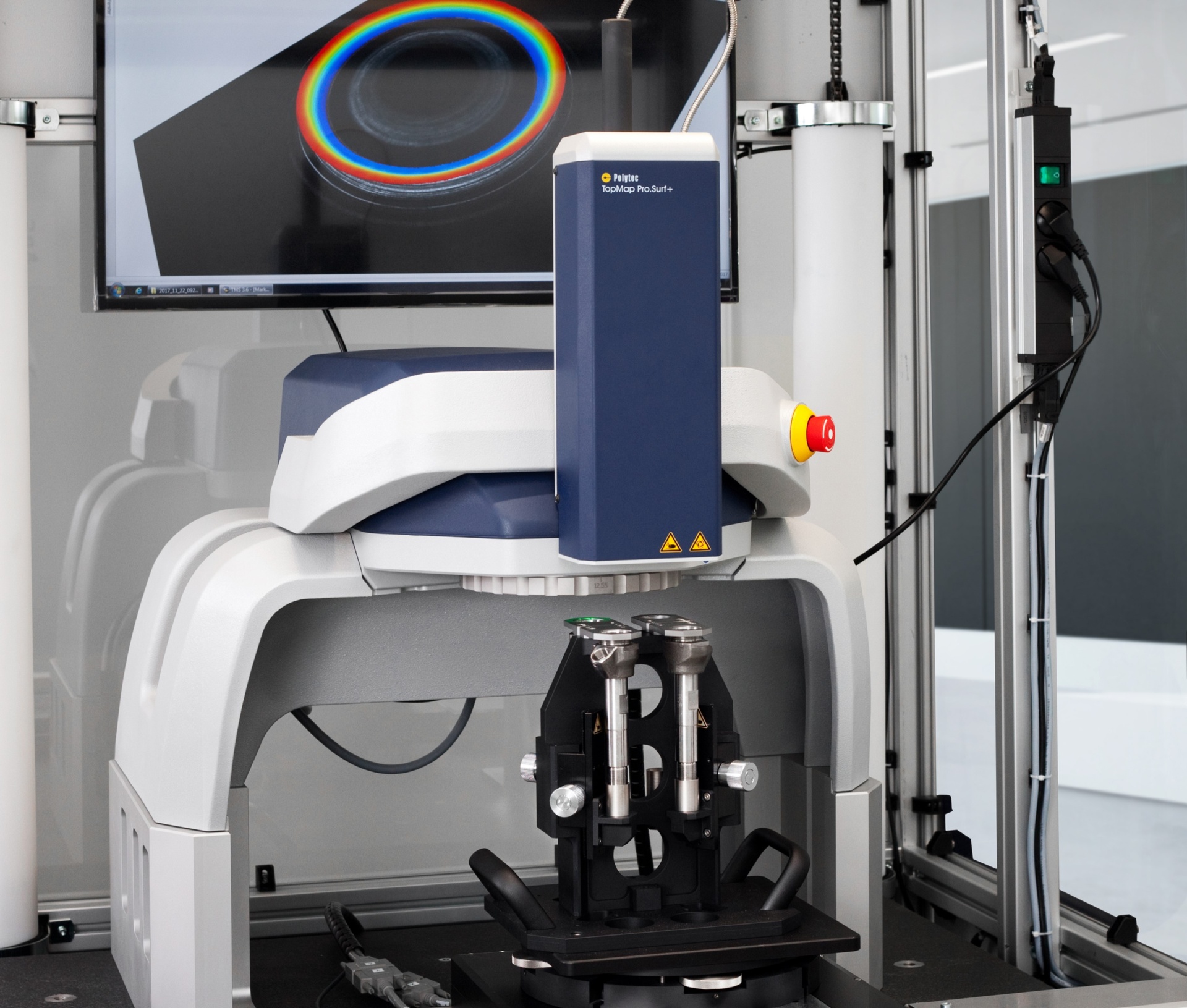

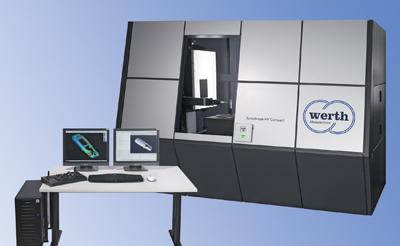

Computed X-ray tomography

Complete and accurate measurement inside and out

The TomoScope® X-ray tomography is suitable for 3D measurements of very large workpieces with higher densities such as aluminum, steel, titanium, composites, ceramics and glass fibre-reinforced plastic and is characterised by its forward-looking modularity.

Fast first article inspections and thus fast product validations reduce process costs. Powerful software and hardware solutions also allow CT machines to be used for high-throughput process monitoring.

Werth ScopeCheck® Optical Multi-Sensor CMM

Werth VideoCheck® HA The Accurate Multi-Sensor CMM