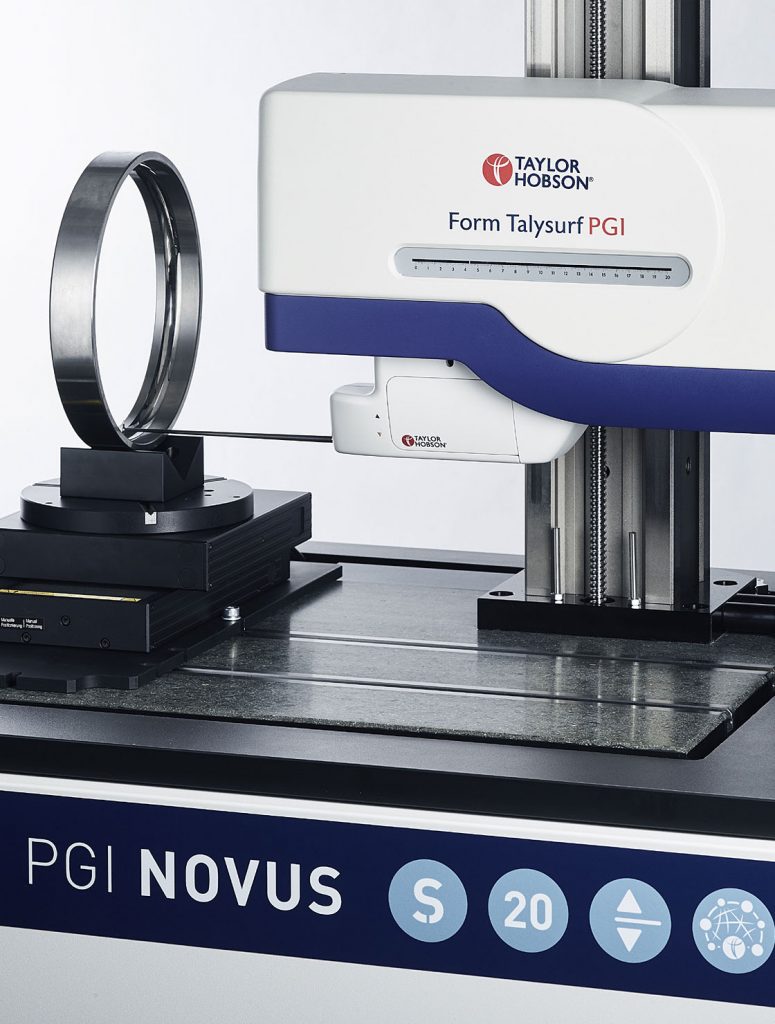

Taylor Hobson specializes in crafting precision instruments for measuring roundness, form, and surface finish, enabling a comprehensive analysis of characteristics such as surface roughness, contour, radius, roundness, straightness and harmonic analysis

Taylor Hobson specializes in crafting precision instruments for measuring roundness, form, and surface finish, enabling a comprehensive analysis of characteristics such as surface roughness, contour, radius, roundness, straightness, and harmonic analysis. These instruments provide essential insights for enhancing design, manufacturing efficiency, and component performance.

Renowned for their cutting-edge brands such as Talyrond®, Form Talysurf® PGI, PGI Optics, LUPHOScan, Surtronic®, TALYScan, Intra, Talyvel, Autocollimators, Micro-Alignment Telescope, and AMECare, Taylor Hobson stands as a global leader in precision measurement technology.

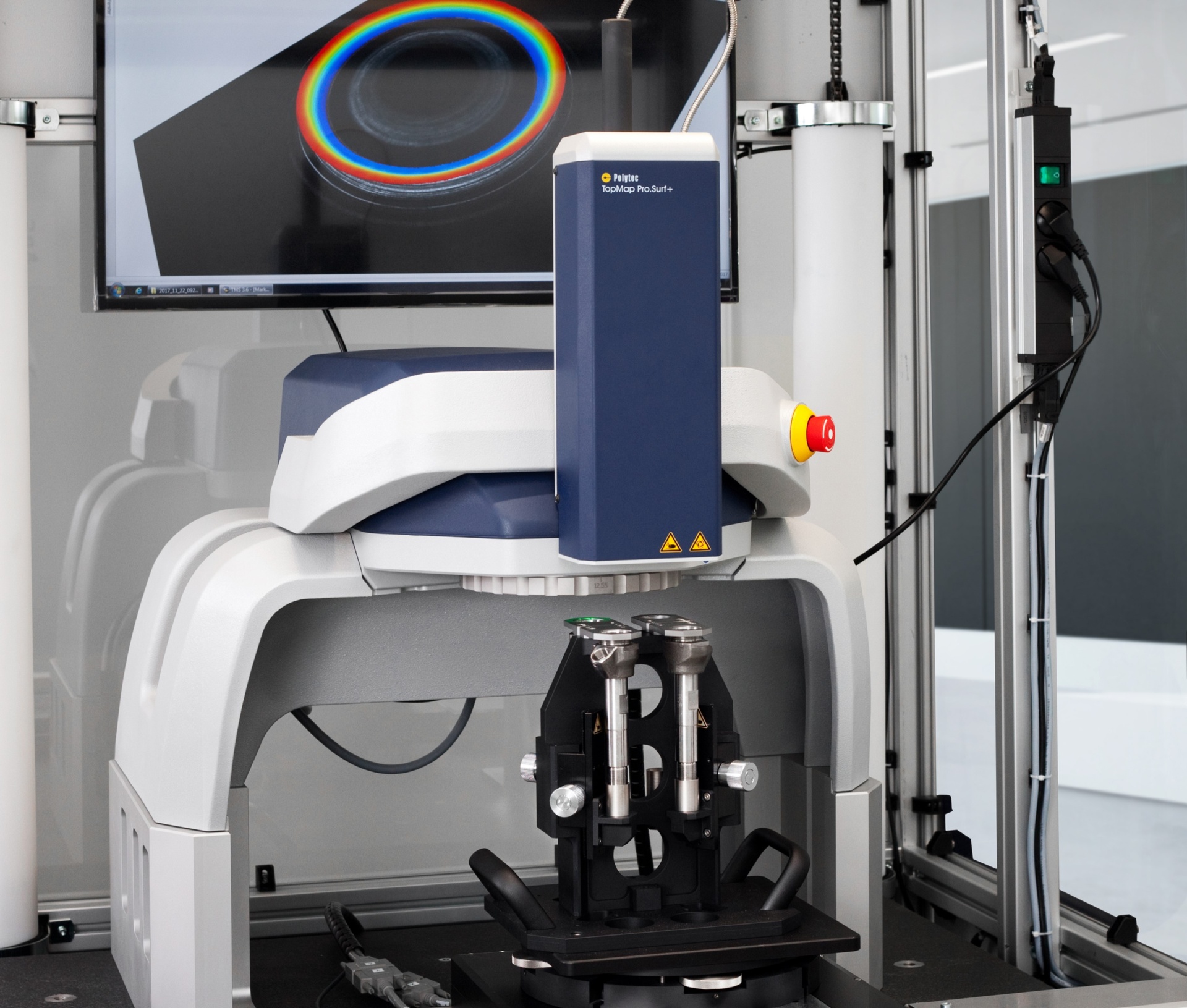

2D-3D Surface Profilers

Discover a comprehensive selection of surface profilers renowned for their unwavering reliability, repeatability, and precision across every measurement scenario. Engineered and crafted to exacting standards, Taylor Hobson products ensure precise measurement of surface finish, 2D & 3D form, surface roughness, step-height, diameter, angle, contour across a wide spectrum of applications including precision optics, cylinder heads and blocks, gears, sheet metal, shop floor, and numerous other manufacturing applications.

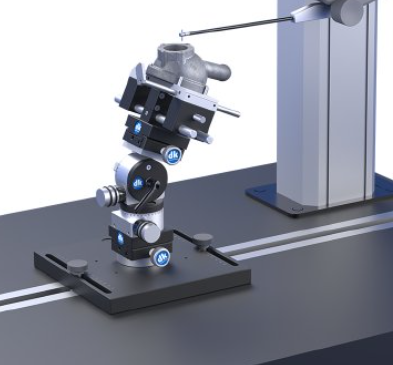

Roundness & Form

CONTACT AND NON-CONTACT ROUNDNESS, FORM, CONTOUR AND CYLINDRICITY MEASURING INSTRUMENTS

The Talyrond® product line offers precise measurement capabilities for three essential performance factors: roundness, surface finish, and contour. Trusted by manufacturers of precision components such as bearings, fuel injectors, crankshafts, turbocharger parts, and beyond, the Talyrond® stands as the top choice for ensuring impeccable quality and accuracy.

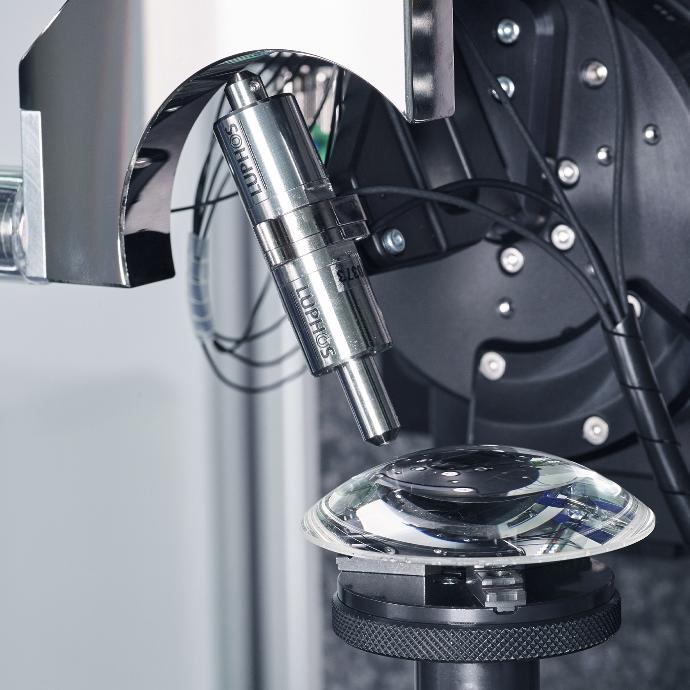

Non-Contact 3D Optical Profilers

Crafted for unparalleled precision, the LUPHOScan series specializes in ultra-precise non-contact 3D form measurements of rotationally symmetric surfaces, including aspheric and freeform variations. These instruments excel in scenarios demanding the utmost accuracy in non-contact measurements, playing a vital role in the manufacturing process. Particularly advantageous for surfaces featuring steep slopes, diverse pitch directions, and compact dimensions, such as smartphone lenses and their molds.